Classic Ford fans rejoice! Auto Metal Direct (AMD) of Buford, Georgia, is now your go-to source for replacement panels, trim, and bumpers for popular old Ford cars and trucks. Time to dust off that old project and get to work.

With a mantra of “Never Too Far Gone”, AMD has been helping the masses restore their cars by producing high quality parts for GM and Mopar classics with great success. Now, the company is taking on the Ford segment. The first of its new Ford components target the Fairlane, Galaxie, Torino, Ford Trucks, and the Bronco.

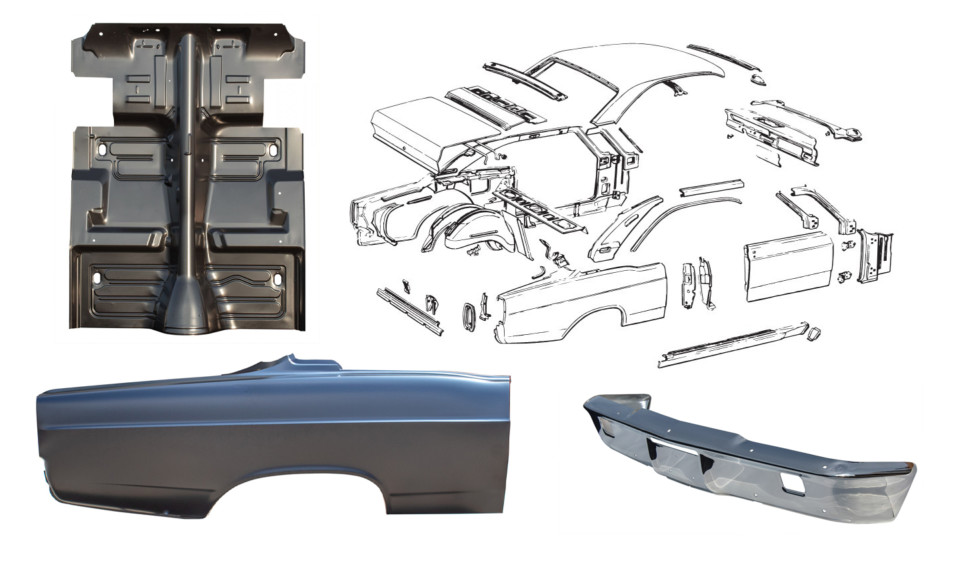

AMD produces full replacement panels for many vehicles including the 1963 Ford Galaxie parts above. The company builds these high-quality components to be exactly like the original Ford panels using new, exclusively-owned tooling dies.

The new component list is massive. Bumpers, fenders, quarter panels, headlights, firewalls, cowls, even trunk floors, and rear bumper fillers! There are many more items on the list; too many to show here. AMD also took the time to develop the necessary brackets and hardware needed for most component installations.

Many of the parts are designed with the fastback variant of the vehicle in mind. “We produce the parts for the most performance-oriented body styles because that is generally where the restoration interest is,” explained Mike Gray, AMD’s general manager. “Often, these were produced in smaller numbers than the regular coupes or sedans, but more people seem to be restoring the fastbacks.”

Oftentimes, fastback parts are larger versions of the non-fastbacks. Meaning, there is a high likelihood they can be trimmed and modified to fit sedans and coupes. Many Mercurys will benefit from the new parts for the same reason.

The Proof Is In The Process

The quality of a part isn’t based on how cool everyone thinks it is — it’s in the construction and materials used — and it’s a painstaking process. When prototyping a new panel, AMD doesn’t take the easy route and use a stamping tool that already exists from another manufacturer. The original Ford tools are long-gone so AMD does the next best thing. They find a car with a pristine panel and surgically remove it from the vehicle. Every flange, every spot weld, and every part is carefully removed and preserved.

“We actually remove every spot weld in a donor car to remove the parts and leave the factory flanges undisturbed. That way, we can produce the part just like the factory would have supplied.” — AMD General Manager, Mike Gray

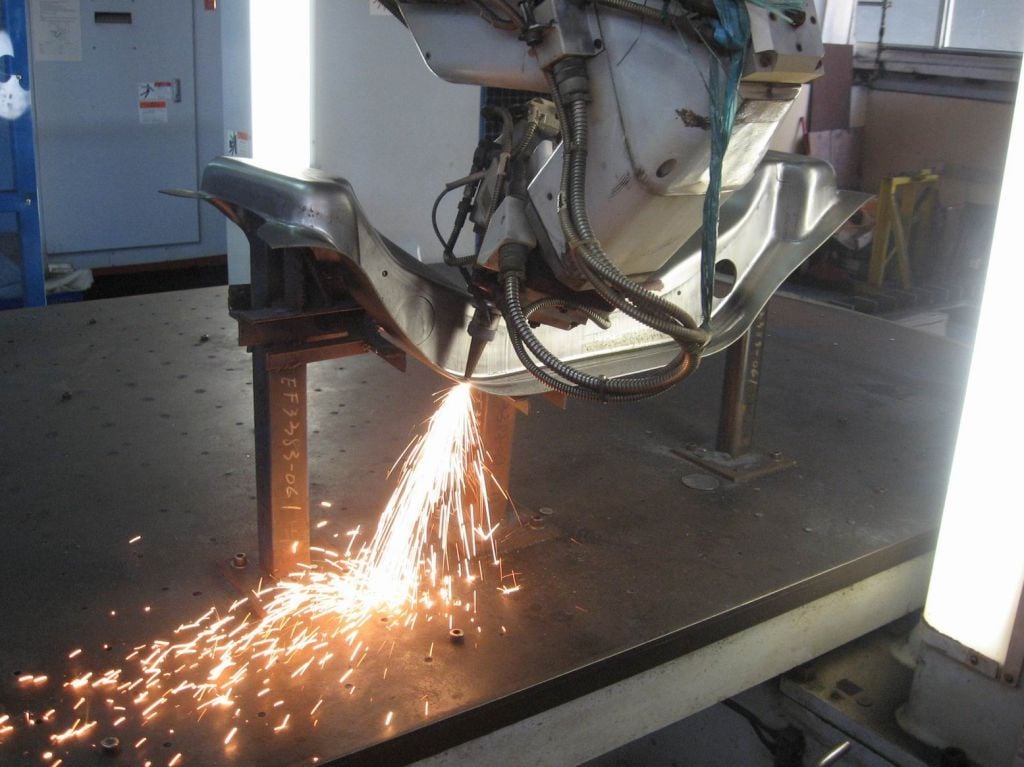

AMD surgically removes body panels from donor vehicles so all the original mounting tabs and part features are undisturbed. The long process provides an extremely high-quality product.

The parts are then digitized using laser measurements for incredible accuracy. The goal is to produce a final part that is an exact match Ford did originally. Tooling is then created. The tooling and parts are manufactured in Taiwan. Domestic diehards may bock, but AMD is producing the tooling outside of the United States for a very good reason.

Most panel tools in the U.S. are made using Kirksite, a moderate-strength alloy. While easy to cast and finish, Kirksite lacks the durability and long-term consistency AMD desires from its parts. Instead, AMD has its exclusive dies built using hardened tooling steel.

The incredibly tough material has a natural resistance to abrasion and deformation. It also has a very hard composition, good for keeping curved and flat panels smooth as well as being able to maintain a sharp cutting edge. The sharp cutting edge is a key positive. This is where the clean-cut, OEM-worthy edges of the panel come from.

Each panel is built using the same gauge steel as Ford did. The panels are full-size — not patch panels — and all feature the same correct-as-original clips, tabs, flanges, bends, and seams. No other panels on the market are this exact to the OEM Ford parts.

The Laser Cutting process AMD uses is state-of-the-art. The system knows exactly where to cut, and how much to cut, every time. AMD also uses robotic welding systems to make sure every part has consistent and strong welds.

Testing

AMD doesn’t stop there. When the prototype comes out of the tool, it is then test-fit on a vehicle. Markups are made and changes are noted, which are then used to modify the tool. Test-fits and modifications happen as many times as needed for a final approved part. After a part is approved, the tooling dies are polished to produce a smooth surface for the finished products.

“We are so confident in the quality and fit of our parts, we have developed our installation center! Cars formerly written off as hopeless are now being given a new lease on life. Since we are actually installing our own parts, we are able to develop parts that fit correctly.”

More About Auto Metal Direct

There are thousands of part numbers already in the full AMD catalog (which includes GM and Mopar as well), and more are being added constantly. The new Ford components are just the tip of everything to come.

AMD aims to be your one-stop source for the highest-quality automotive parts on the market. Its product line is constantly growing and is available either directly or through distributors. The company attends many enthusiast shows throughout the year and has a showroom at their main facility.

AMD also attends many shows throughout the year. They bring parts out for customers to see first-hand the quality that comes in an Auto Metal Direct part.

Auto Metal Direct warehouses all of its products ready to ship to customers from its facility in Cleveland, Georgia.

Auto Metal Direct’s Installation Center

AMD launched its own Installation Center specifically for installing its body panels. Located adjacent to the Georgia warehouse, the Installation Center specializes in replacing body-shell components though it’s not a full body shop. Currently, it is open to working on 1967-69 Camaros, 1966-72 Novas, and 1966-72 GM A-body vehicles. Stay tuned, however, because the AMD Installation Center will likely be adding 1968-70 Mopar B-bodies and 1970-74 Mopar E-bodies to the lineup.

The AMD Installation Center is a for-hire job-shop specializing in replacing worn out and wrecked body panels with new AMD components.

What’s Next?

AMD has been working on launching the expanded Ford program for the last two years. New parts are arriving weekly and will be fully launched by the end of the year. You may have noticed, there is no mention of Mustang parts. The problem is market saturation. The Mustang is arguably the most popular Ford classic; many companies have already produced panels and other restoration parts for them.

“We have no plans to get into the Mustang business at this time,” Gray said when asked. “Although we get many requests to produce better quality Mustang parts than what is currently on the market, we don’t feel the Mustang market will support the prices our new tooling requires to recoup our costs.” This is the unfortunate side of the business. As much of a hobby as it may be for all of us, including the folks at AMD, business is business.

AMD will carefully watch the market and will investigate again as its Ford product line continues to grow. In the meantime, it’s already looking at other models to support including Falcons, other years of Galaxies and Fairlanes, as well as even more components for trucks from 1948-79. There is even word of a special focus on 1973-79 Ford trucks.

Check out the websites for Auto Metal Direct and the AMD Installation Center for more information. AMD also has a growing YouTube channel with tips and install videos.