Here at Ford Muscle, you’re probably used to reading all about the hottest performance parts in the industry and the applications they’re intended for. It’s not every day that we’re invited to see behind the scenes of the development of a particular product, but recently, we spoke with drag racer Mike Jovanis about Baer’s Mustang SS4+ Drag Brake Systems. Jovanis was an integral part of the development and evolution process, and he was able to give us some insight on the brakes which are built for Fox-body Mustangs and several other applications.

Throughout this story, you'll see a mix of photos taken by Jovanis during the SS4+ Drag Brake development process, along with photos of season one of the $10K Drag Shootout, when several of the cars in competition were equipped with Baer's SS4+ systems.

If you’re not familiar with Jovanis, you should be. He wields a flawless Deep Shadow Metallic Blue Mustang in NMRA’s True Street category, ripping down the track at an average of seven seconds – that’s after a 30-mile street cruise, with no breaks in between (and no popping the hood in the staging lanes). It’s a far cry from the NMRA Street Outlaw and Renegade competition, even if it is in the same power range. And honestly, it’s super impressive to watch. Because of the way Jovanis operates his 3,400-pound Fox, his brakes not only have to stop him at high speeds in the shutdown area after trapping somewhere in the ballpark of 180 miles per hour (sometimes without the help of a parachute), but they also need to stop on the street, especially while towing a trailer during Drag Week. Reliability is of the utmost importance.

Jovanis tells us that this particular kit was designed for fast, full-weight street cars like his own, and they were built specifically with several goals in mind. They had to perform well on heavy cars, they had to last long on street-driven cars, and they had to offer as much braking power as possible in “a package that fits a 15-inch wheel and double beadlocks in the rear” while also looking good. Of utmost importance was that the system could stand up to the torture that comes along with events like Drag Week. This made for a completely different design than those built to be lightweight with the purpose of slowing down lighter weight drag cars, usually with the help of a parachute.

Previously, Jovanis had been utilizing Baer’s SN95 Front Spindle Kit with the Dual Caliper Rear Kit for over three years, when he made the switch early in 2015.

He did so after a series of upgrades including a new Haltech ECU, a fresh DiSomma Racing Engines engine, as well as a new turbocharger from Forced Inductions. He says that at the time, he was consistently trapping over 180 miles per hour.

“As the car continued to progress from a performance perspective, we were consistently seeing trap speeds over 180 mph,” he explained. “This made me think more about suspension and alignment and I set out to make some changes to get more positive caster for high speed stability.”

The SN95 spindles that Jovanis’ Fox-body sported limited his car to about 2.5 degrees. His wheels were pushed out just slightly due to caliper placement and spindle width. While he admits this wasn’t causing any issues for him, fixing this was on his to-do list when time would allow. Some winter downtime finally brought the project to a start, and he got in touch with Baer to get rolling.

Kit Advantages

Jovanis broke down the entire list of advantages that come with the SS4 + Drag Brake System. Installation does not result in additional track width which DOES result from installation of an SN95 spindle, and the caliper is moved in-board, utilizing the dust shield bolt holes. This reduces the need for a wheel spacer. The kit ships in two boxes, and includes calipers, brake pads, rotor and hat assemblies, and -3AN fittings w/ copper crush washers. It should be noted that the kit does not include spindles/hubs or brake hoses, and while this kit is designed to be used with stock Fox-body spindles and hubs, Baer also offers a kit for those utilizing 94-04 Mustang SN95 spindles and hubs.

The system arrived in two boxes, packed carefully to protect the contents. Jovanis began by marking the factory caliper mounting ears.

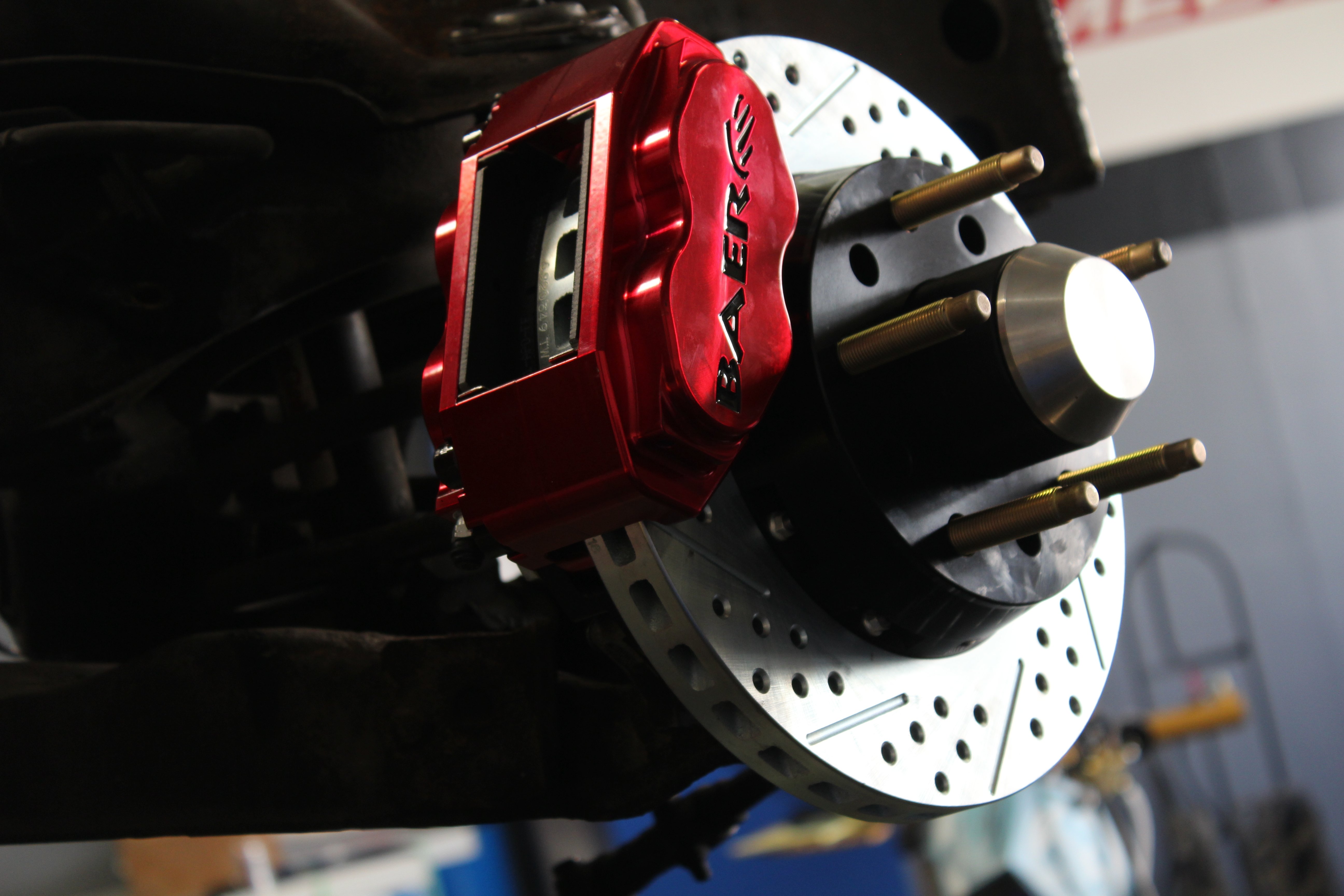

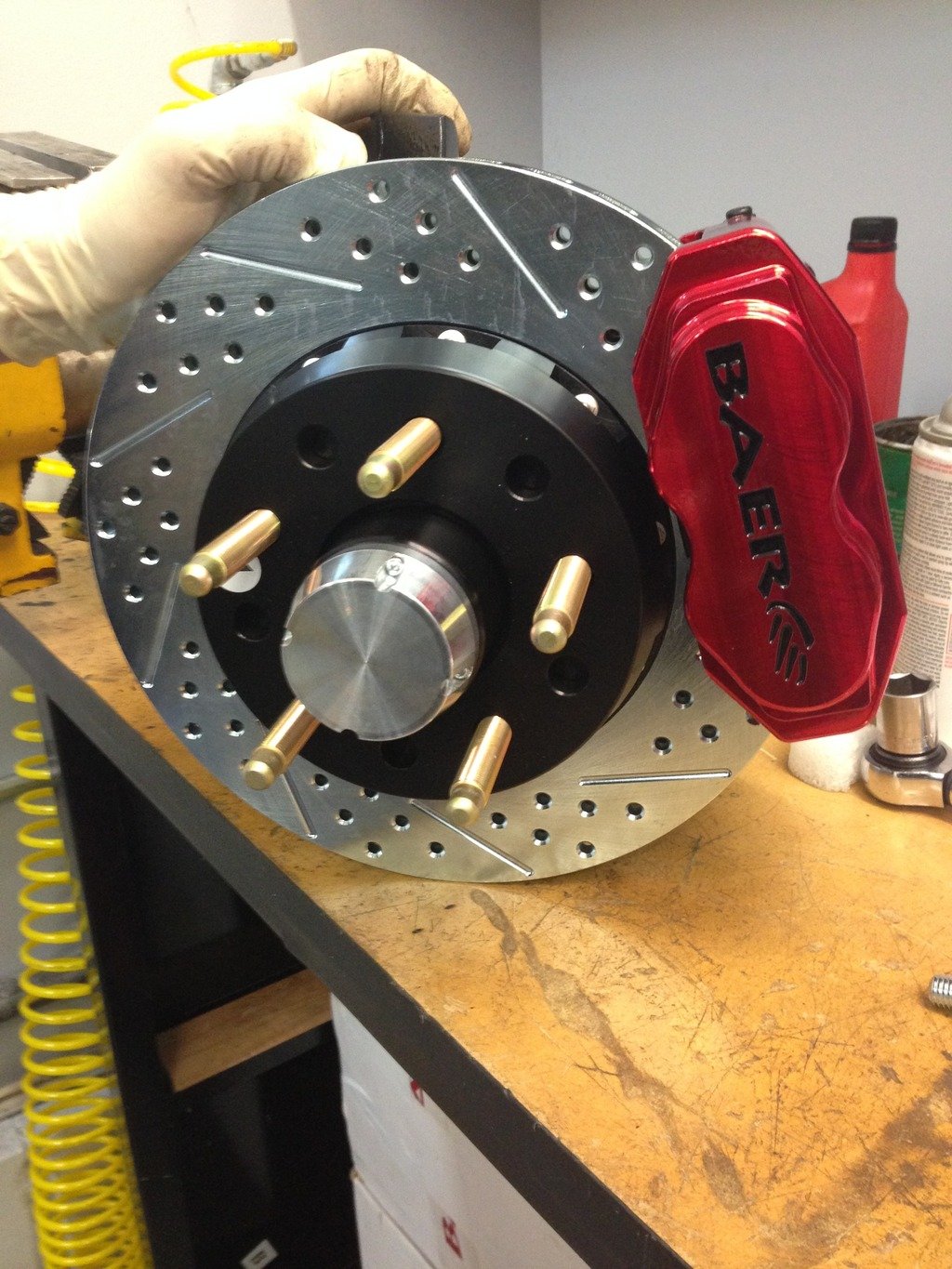

The included calipers are of the S4 variety and feature four 10mm cross bolts for maximum stiffness, as well as stainless steel abutments and noise suppression springs. The calipers were designed with an internal crossover design and feature dust and weather seals, as well as hard anodized aluminum pistons. A common 4-piston pad is utilized for easy replacement. Correct banjo style fittings are used in place of pipe thread. Baer offers custom colors, though clear or Fire Red are standard, and the machined Baer logo is hand painted. Perhaps best of all, the calipers are 100% made in the USA from US-sourced materials.

Going back to that track width point, the track width is nearly factory. We say “nearly” because of the intentional .1-inch built into the rotor hat for wheel clearance. Jovanis explains that this is significant seeing as most brake systems change the track width without notifying the customer.

The resulting geometry is better for drag racing in both the bump steer and caster departments and is available starting at around $1,095.00 depending on options like caliper color, rotor finish, and more. Baer offers two configurations for this kit: one for 1987-1993 Mustang spindles, and the other for the Racecraft 2-inch drop spindle. The caliper placement is optimized for each configuration. In the following pictures, you’ll see the Fox spindle bracket, which is different from the Racecraft 2-inch drop spindle bracket in that it rotates the caliper upward.

A porta-band saw was used to create raw cuts, which were then cleaned up with a grinder. The factory dust shield bolt holes were tapped after being drilled to a larger diameter.

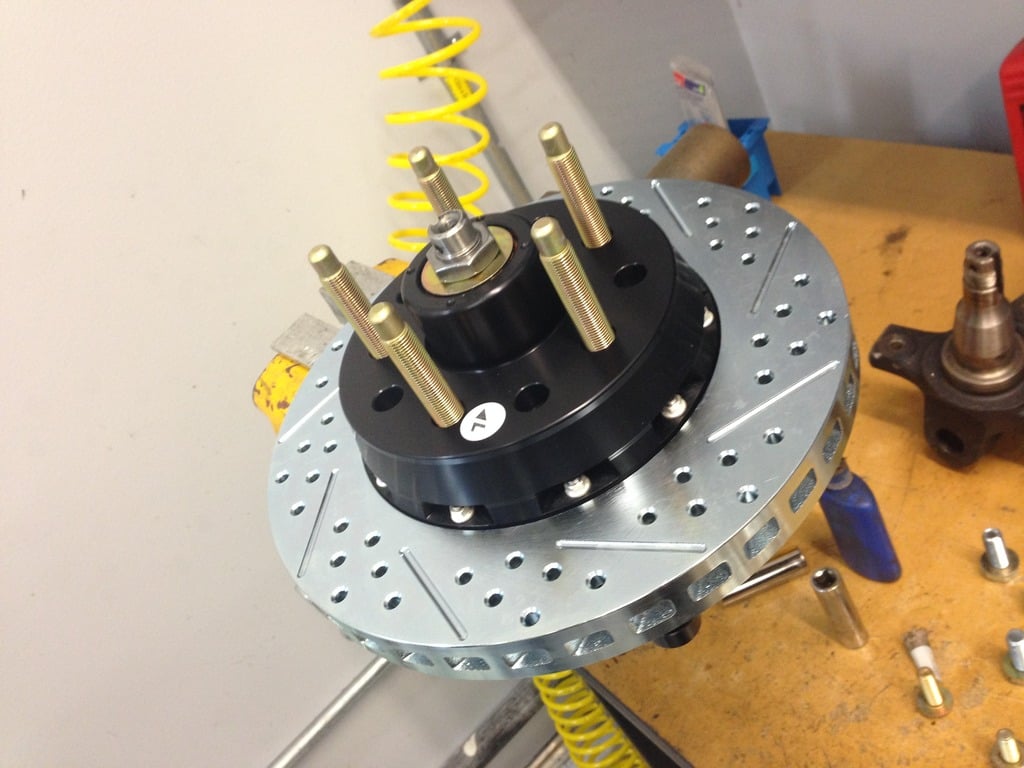

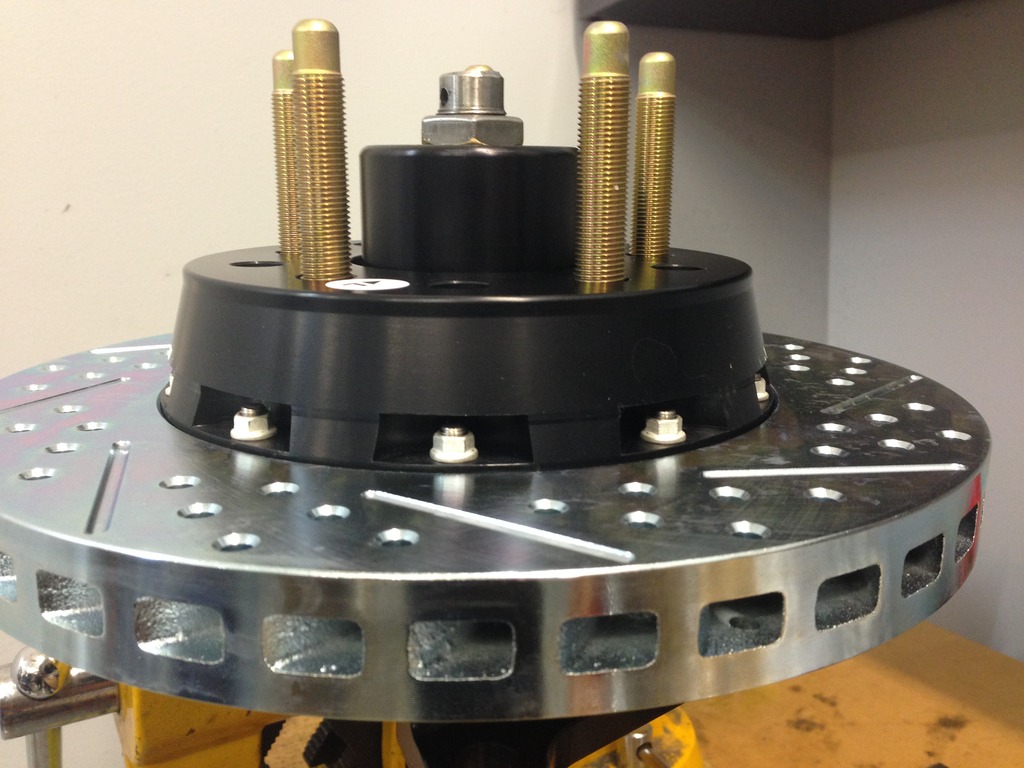

Used in the kit are a one-inch thick directionally vaned 11-inch, 2-piece, slotted, drilled, and zinc-plated rotor with a black anodized aluminum center. Jovanis says that this type of rotor may weigh a bit more than lighter weight systems, but it is made to survive the abuse associated with high powered true street cars. He notes that the 11-inch outside diameter will fit in most 15-inch wheels (including double beadlock rear applications like his own).

Moving the caliper in-board for wheel clearance means that A-arm clearance must be verified once the car is back on all fours. Jovanis’ Fox was equipped with an older Flaming River manual steering rack which had no limiters, allowing for a broad range of motion. Jovanis added limiters to keep the caliper and bracket away from the A-arm, and noted that because the Fox has a spool and manual steering, this didn’t really make a practical difference.

While the system on Jovanis’ Fox fits 1979-1993 Mustangs equipped with 1987-1993 Fox spindles in four-lug and five-lug configurations, there is also a kit offered for SN95 Mustangs. If your Fox is already equipped with SN95 spindles and you’re not wanting to make the conversion back to Fox spindles like Jovanis did, Baer’s SN95 kit will fit on Fox-bodies as well.

Installation

First, Jovanis said that the Fox spindle had to be modified. The factory caliper mounting ears were marked and removed. Jovanis utilized a porta-band saw for this part. A grinder was used to clean up the raw cuts, making the spindle look neat and clean. The dust shield bolt holes needed to be tapped after being drilled to a larger diameter.

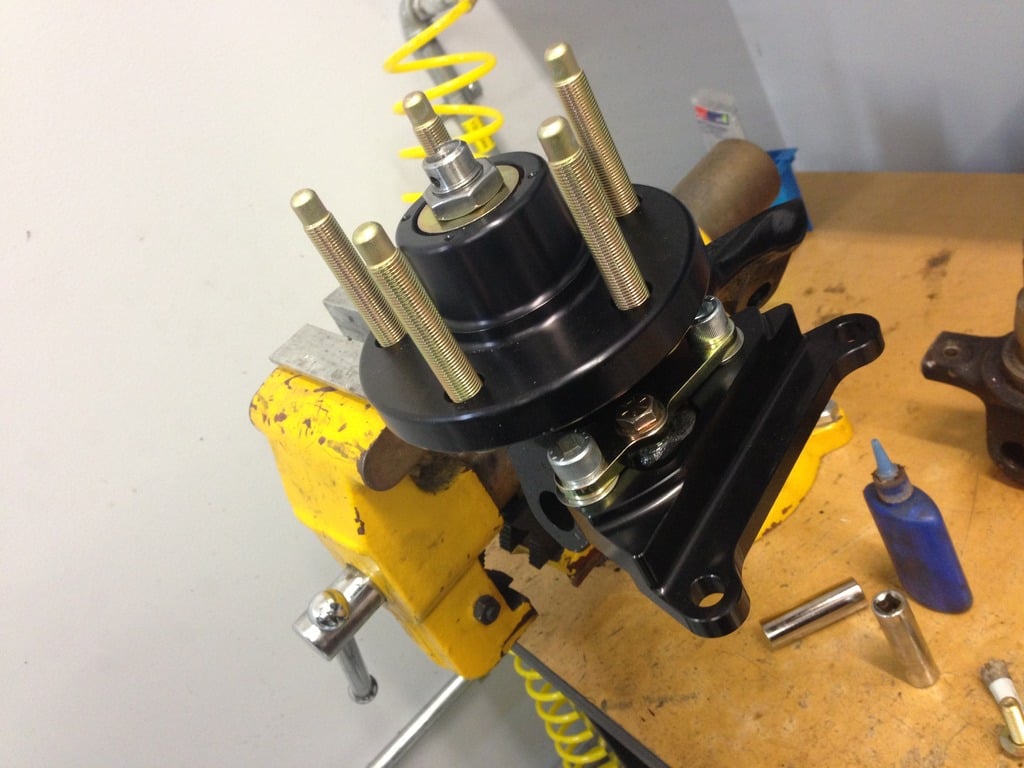

The mild steel bracket was installed, and a black anodized billet intermediate bracket was then mounted to the mild steel bracket.

Then, Jovanis could get started on assembling the brake system onto the spindle. He began by laying out the small parts. The mild steel bracket was installed by mounting to the bolt holes that were tapped. Next, the black anodized billet intermediate bracket was mounted to the mild steel bracket.

“This two-piece design allows shimming the caliper if needed since there are sometimes variances in spindles,” Jovanis explained.

The Fox spindle was converted to use a hub that allows a slip-on rotor. The hub in question is anodized billet aluminum and comes assembled with pre-packed bearings for an easy installation. The rotor was then test fit.

The Fox spindle was converted to use a hub that allows a slip on rotor, and the rotor was test fit.

“Not only did we eliminate the additional track width from the SN95 spindles,” Jovanis said, “but we also eliminated the 3/8-inch spacers we were using, effectively bringing the wheels in over .5 of an inch.”

Post-installation, Jovanis took the car in for a lengthy alignment session. Jovanis also utilized parts from UPR, including a K-member, A-Arms, and fixed-mount race caster/camber plates. The installation of the Fox spindles in addition to the caster/camber plates allowed the achievement of 5.5 degrees of caster, compared to the SN95 spindle and street caster/camber plate combination’s 2.5 degrees.

The finished product during development, and then on a $10K Drag Shootout car.

Following the installation, Jovanis headed to NMRA’s Spring Break Shootout in Bradenton, Florida and made a personal best pass of 8.19 seconds, winning the race with an 8.31 second average of three consecutive runs. He followed this successful race up with eleven more True Street wins and a successful completion of Drag Week (while towing a trailer).

“Since the install, the car has been a best of 7.55 at 181.35 and is one of only two cars to have achieved a 7-second average twice in NMRA True Street, with a best average of 7.83 seconds,” Jovanis told us. His success confirms what he already knew. “These are the best brakes you can put on a true street car.”