The name “Godzilla” is menacing. It carries a connotation of immense power and the ability to conquer. As a racer or street enthusiast, you’d want Godzilla under the hood — especially if it’s the new gas-burning Ford 7.3L V8 that carries the animalistic moniker.

In good, old-fashioned hot rod speak, 7.3 liters translates to 445 cubic inches, giving “Godzilla” big-block displacement, but in a small-block package. In technical terms, you have to look deeper than the cubic inches to determine whether an engine is a big- or small-block. In actuality, a big- or small-block is based on bore spacing, which is the separation of the cylinders measured center to center. With a 4.53-inch bore spacing Godzilla is more small-block than big-block. And by God, don’t call it an LS clone, either. Ford has been using skirted blocks and heads with equally spaced intake and exhaust ports for decades.

Size is More Than Just Displacement

As for physical size, the 7.3L is 25.5 inches wide at the top of the valve covers, which is about two inches wider than a typical 351 Windsor. It’s 24 inches long (351W is typically 22.5 inches) so it will fit in just about anything.

As delivered in the 2021 F250, Ford’s new V8 delivers 430 horsepower at 5,500 rpm and 475 lb-ft of torque at 4,000 rpm. And while these are not ground-breaking numbers in terms of a racing engine, there’s much more to the story.

Wolfe’s efforts on the 7.3L are impressive. While he has a great team working on this project; he is the engineer, engine builder and will be the driver, too.

Godzilla’s magic lies in the design and architecture. It has a sturdy iron block with a 6-bolt main journal configuration for the forged-steel crankshaft (similar to the 4.6L DOHC and 5.0: Coyote). The heads flow 300 cfm stock and with the right porting, can flow upwards of 400 cfm (and that’s without any welding). The bellhousing pattern is the same as the Coyote and Mod Motor’s mounting pattern. In other words, Godzilla is ripe for making horsepower.

Other features from the factory include a 60mm cam bore, a chain-driven variable-volume oil pump and variable cam timing. Up top, Godzilla wears aluminum heads with big valves capable of making 600-plus horsepower with only a light clean-up on naturally aspirated combinations, and over 1,450 horsepower in fully ported trim with boost — which is impressive for stock castings.

This boosted Godzilla breathes through a 105mm mono-blade oval throttle body with matching heavily radiused oval velocity stack.

Looking to go from stock to rock, Brian Wolfe, who is the former Director of Global Engine Engineering at Ford Motor Company, has taken on the task of experimenting with a variety of 7.3L combinations. He’s dyno-tested Godzilla engines in a variety of configurations from mildly modified to fully built with boost.

Wolfe, who now operates Willis Performance Enterprises in Willis, Michigan, invited us to tag along during the bevy of experiments. His findings are both interesting and impressive to say the least. But more than just experiments, Wolfe is offering his packages to customers wanting a Gozdilla of their own. To obtain one, you can look to Ford Performance Parts (P/N: M-6007-73) for the crate engine, or you can hit up Wolfe on the web. Another option is to keep your eyes open at the local wrecking yard.

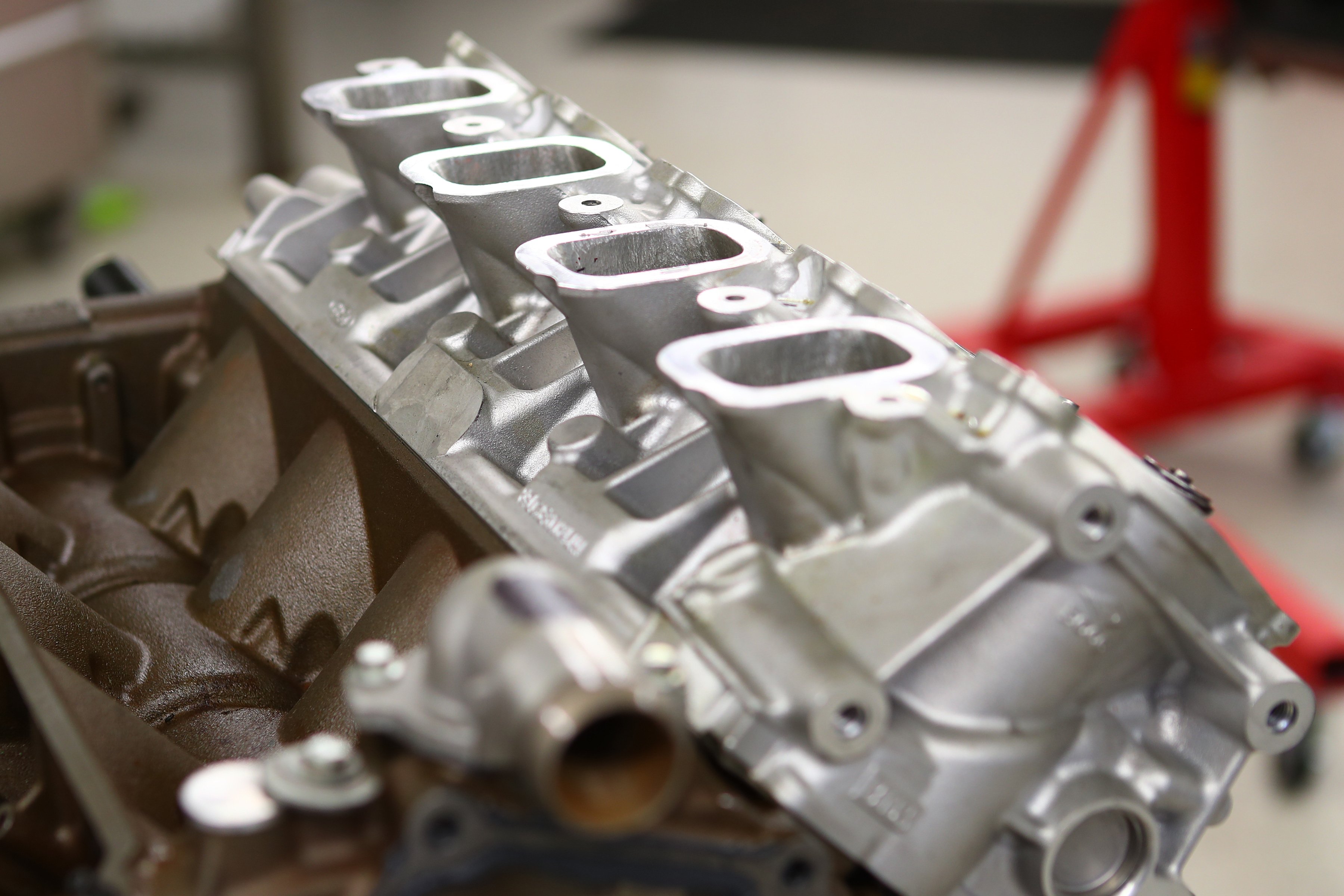

Prior to the blower, Wolfe tested the engine naturally aspirated with this awesome billet intake (still with all the blower internals used). The combination made almost 800 horsepower without being optimized.

Diving Into The Combo

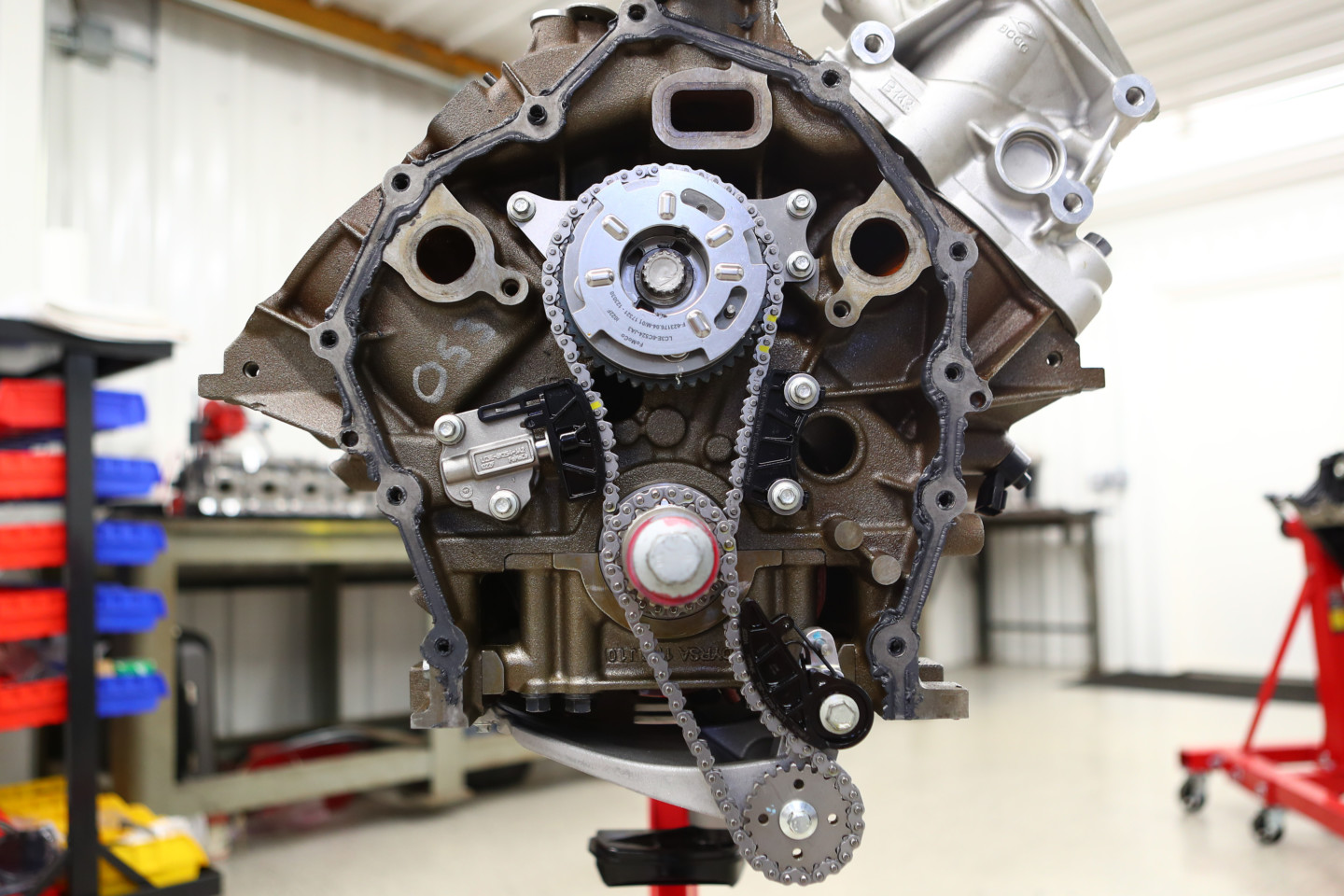

Before digging into the dyno results, let’s get you up to speed on the technical attributes of this new V8. The 7.3L is based around a cast-iron block featuring 4.220-inch bores spaced 4.530 inches apart. Deck height is 9.650 inches from the crankshaft centerline and the forged-steel crank is retained with 6-bolt main caps. Stock stroke is 3.976 inches and the crank has 2.660-inch main journals (which are shared with the 6.2L Ford V8) and 2.086-inch rod journals (the same as the Coyote). You’ll note there is a soft cut at the top of the deck surface for coolant flow, but this hasn’t proven to be an issue so far.

The OEM cylinder heads are aluminum and have 2.17-inch (55.13mm) intake and 1.66-inch (42.53mm) exhaust valves that sit at an 8.8-degree valve angle. The valves are also canted at 1.8 degrees. Cam lift is .539 inch (13.67mm) intake and .600 inch (15.26mm) exhaust and factory compression is 10.5:1. Stockers have cast aluminum pistons, a composite intake (designed for use in a truck) with a single 80mm throttle body, an 8-quart oil pan, and the firing order is 1-5-4-8-6-3-7-2. The weight of the 7.3L is roughly 540 pounds.

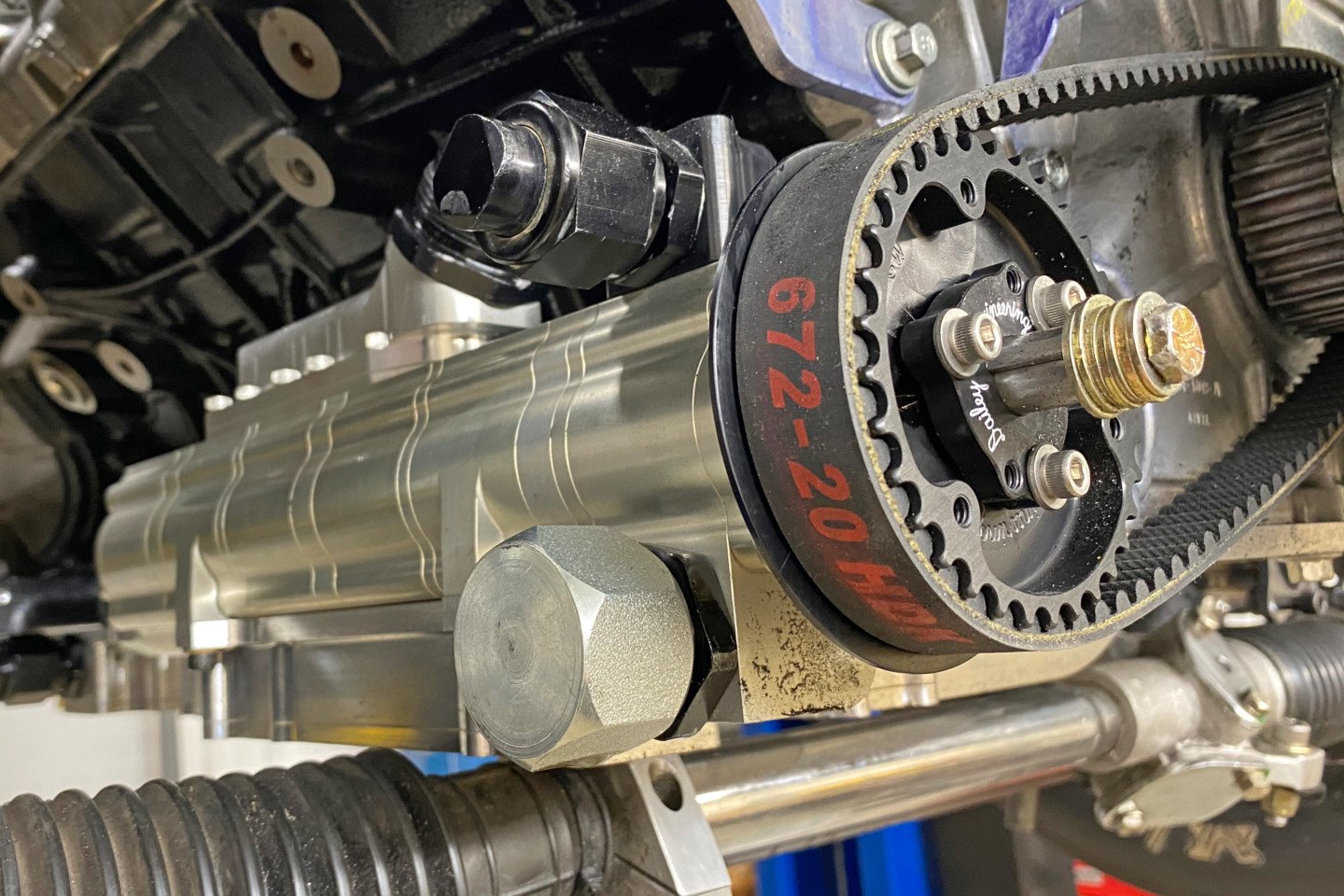

This is the front-drive system on the 7.3L. It utilizes variable cam timing and a “Jackshaft” to drive the variable displacement oil pump.

Crank It Up

Wolfe’s plan is to explore the limits of the platform, with the end goal of building a race version capable of powering his 1993 Mustang LX in John Sears’ Ultra Street and NMCA Xtreme Street competition. In his estimation, in order to run at the top of the class he’ll need upwards of 1,700 horsepower. Of course you have to start somewhere, so Wolfe began with a base build, he then spent the better part of 2020 refining the combination. After a bunch of naturally aspirated trials, he added a 3.0L Whipple and gave it the gusto.

“The big thing about going with this engine was working with common factory high-volume production Ford parts,” says Wolfe. “For me, the last 15-20 years of racing was done with aftermarket parts; whether it was a Windsor-based billet block or a 5-inch-bore-space Hemi-style engine. The fact that I can now race with factory Ford parts is exciting. Guys have been racing with the Coyote in many classes and they do very well. There’s Chris Holbrook, MMR and Tony Bischoff to name a few, plus all the guys running NHRA and NMCA Cobra Jets. The 7.3L, however, is brand new to the market and I wanted to try racing with the ‘other’ current Ford platform.”

Wolfe began dyno-testing with a 7.3L that had the front engine dress removed and headers added. The 430-horsepower stock output, tested using SAE J1349 standards, was done with factory air inlet, front-engine dress, full exhaust, and production truck engine calibration. Basically, it’s tested as it sits in the truck.

Using typical racer net (and correcting to standard temperature and pressure), output jumps to just over 500 horsepower. That’s because the engine now has an unrestricted throttle body, open headers, electric water pump, and the front engine accessories removed. Added to that is a maximized EFI calibration for premium pump fuel.

Wiseco 12.5:1 compression pistons (left) with MGP aluminum rods swing on the stock crank in this supercharged Godzilla.

Moving to the Next Level

Next, Wolfe tore down his Godzilla and rebuilt it with typical hot rod tricks to withstand the rigors of supercharging. He worked with key companies to develop parts critical to turning up the wick, such as rods, pistons, camshaft and valvetrain. He kept the stock forged steel crank, but added MGP aluminum connecting rods, Wiseco 12.5:1 pistons, Jesel keyed lifters, Jesel rocker arms, and he worked with Charlie Westcott at Militia Performance, who developed a custom-ground solid roller camshaft that exceeds .900-inch lift and has over 275 degrees of duration at .050-inch.

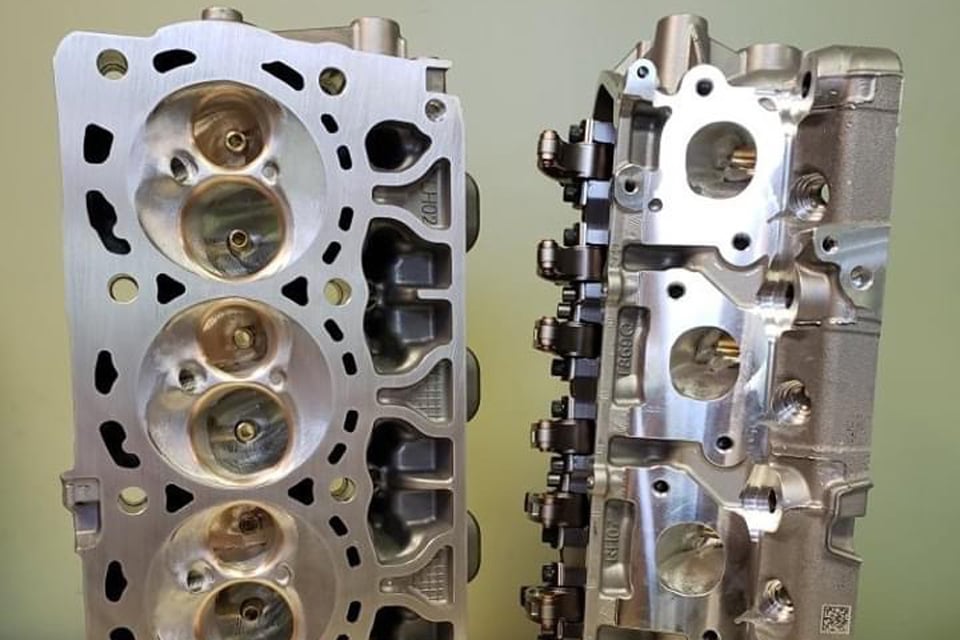

Meanwhile, Dave Visner at Visner Engine Development prepped a set of heads. “We used stock castings that were CNC-ported and we did work in the chambers as well,” says Wolfe. “Dave then trimmed the spark plug bosses and the valves were increased to 2.25 inches on the intake side and 1.700 inches on the exhaust. He added PAC 1357 springs and Jesel shaft rockers. It’s important to note that no welding was done to the heads at this time (this means the ports remained in the stock location). With the work complete, the intake ports flowed 395 cfm and the exhaust flowed 235 cfm.

Wolfe chose a Dailey Engineering dry sump system with a low-clearance billet oil pan. The Dailey system is unique in that it scavenges through integrated channels in the pan, not via external lines.

Wolfe assembled the engine, but before going with the blower he traded the production truck intake for a one-off billet tunnel-ram style intake with a round 105mm throttle body. He returned Godzilla to his Superflow dyno where it developed 790 hp at 7,900 rpm and 560 lb-ft of torque.

“I was pleased with the performance, given it wasn’t optimized for a naturally aspirated application,” explains Wolfe. “It has a wide lobe separation cam suited for the blower with only 12.5:1 compression. Plus, it still has the stock oil pan and pump. So with more compression and a cam suited for natural aspiration, I feel it could make over 900 horsepower. And remember, this is with a production block, crank and heads.”

Wolfe is methodical, so once again the engine was torn down and inspected after testing. He was happy with the condition of the bearings, rings and the pistons, so he reassembled the beast and bolted on the boost-maker — an intercooled Whipple 3.0L supercharger.

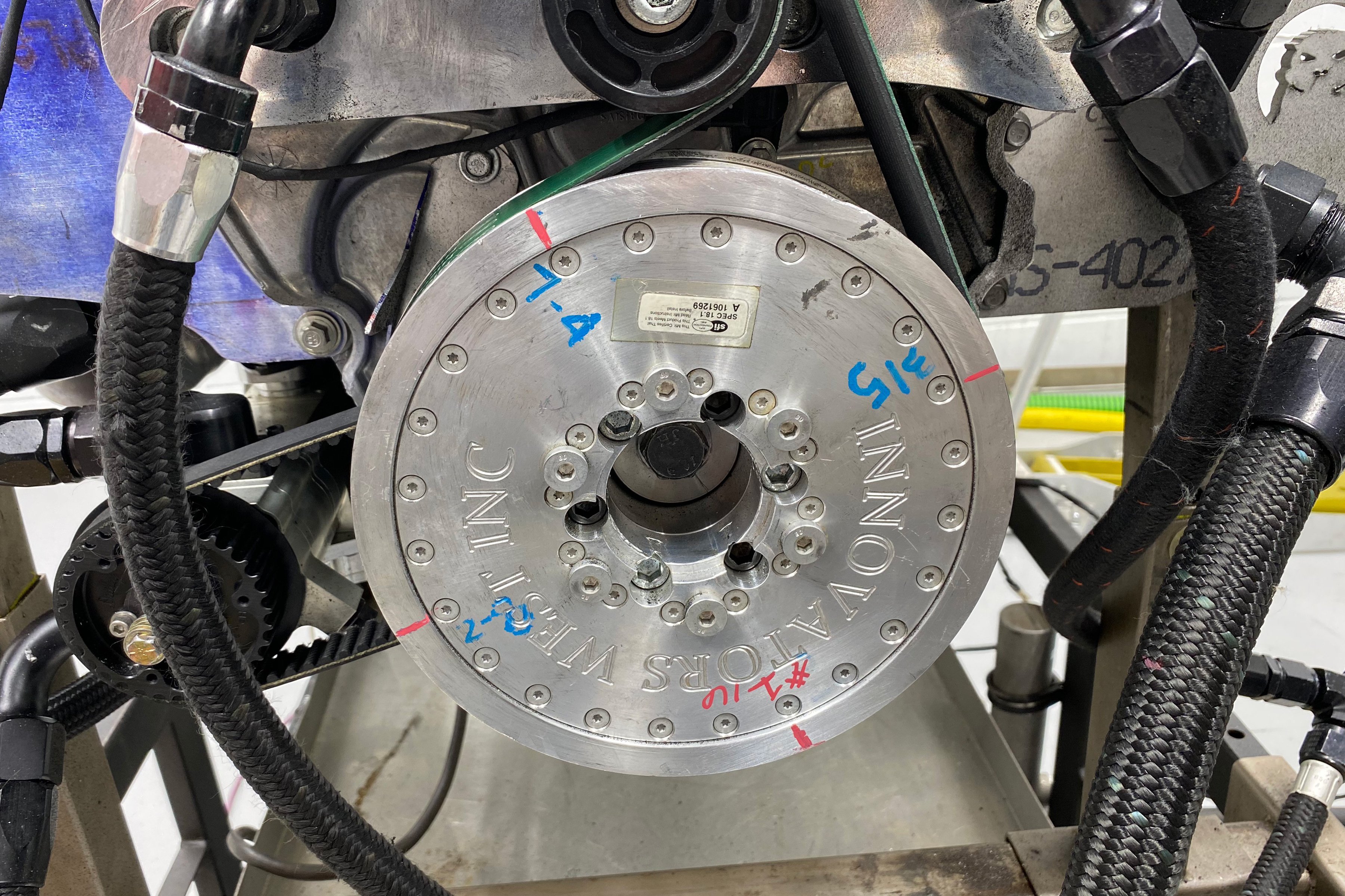

Whipple GripTec 2.65-inch upper pulley served as a good starting point making ample boost when combined with an 8-inch SFI-approved lower pulley unit from Innovators West. . The engine achieved 16 psi., but Wolfe was looking for more blower speed and ultimately more boost. He recently ordered a 9-inch lower pulley to test.

Force Feeding the Combination

With lofty goals, the next dyno session would be the biggest test to date, and one that would tell if he’d be remotely competitive in Ultra Street. “The top cars are making over 1,700 horsepower, so that’s the immediate target, but it may take some effort to get there,” Wolfe states.

“For the blower build we used a dry-sump pan by Dailey Engineering and everything else remained the same, even the rods, bearings, rings, and pistons from the last test went right back into the engine.” Up top now resides a Whipple 3.0L intercooled blower similar to the one used on the 2019 5.2L Cobra Jet Mustangs that are commonly found in Factory Showdown racing. To get the boost levels where he wanted them, Wolfe installed an 8.0-inch pulley on the crank and a 2.65-inch blower drive pulley.

Dave Visner of Visner Engine Development worked his magic on the stock aluminum castings. The factory heads were CNC ported but no welding was done. This means the ports stayed in the stock location, yet still flowed almost 400 cfm (left, center). On the right are the Manton rockers used early on but later switched to Jesel.

With excitement and energy in the air, Wolfe made a final check of the throttle actuation then he pressed the “start” button on the dyno console. After a few tries, Godzilla roared to life with a crisp cackle from the headers indicating big things were about to go down. There was also race gas in the fuel cell instead of the usual 93-octane. The 7.3L had a menacing attitude with a sinister note at idle.

After warming the engine, Wolfe made a few pulls with low timing to ensure the engine was happy. The vitals looked good, so he cranked the sucker up, revved it a few times and pushed the throttle to the stop. Godzilla made a growl as the Superflow dyno applied its load, then, with the monoblade throttle plate laid wide open the revs began to climb.

The Gen-5 3.0-liter Whipple twin-screw supercharger used on the Godzilla is similar to the units used on the Cobra Jet Factory Showdown cars, as well as the one we installed and tested a while back.

The revs came up and the exhaust was ear-piercingly loud. It made a much more aggressive sound with the blower and as boost came on it changed from a howl to a thunderous cry. Soon, the internal-combustion symphony reached full song just as Wolfe’s self-imposed redline of 7,900 was reached. He hiked back on the throttle control to prevent over-revving, cut the ignition and silence came over the room. Our attention jumped to the computer monitor, where the display showed Godzilla produced 1,450 horsepower at 7,800 rpm and 1,030 lb-ft of Mustang moving torque!

“That’s 1,450 horsepower at 16 lbs of boost,” says Wolfe. “The timing is still a bit conservative, and it didn’t get close to maximum blower speed. I’m happy with the performance of the heads and flow downstream of the blower; this tells me three things. The low boost indicates the valves, ports and valve events are reasonable. The second thing is that I need to get the blower speed up. Lastly, we had some belt slip, so I have to work on that, too.” Wolfe already ordered a 9.0-inch damper and has added Grip Tec finish on all the pulleys.

“I could continue my development, but at some point you have to shoot the engineer, put the engine in the car and go testing,” Wolf laughs. “And that’s where we are. I expect eventually it will go north of 1,600 horsepower, but I’m not by sure how much. We’re doing a few final touch-ups on the car and the plan is to be testing by mid-March. If it goes well, we’ll be racing and that’s pretty exciting.”

While this is an aggressive build for heads-up racing, Wolfe offers a variety of packages for all types of projects. He has worked closely with Callies on cams and connecting rods for different combinations starting at 600 horsepower and it goes up from there. He can build the Godzilla of your dreams or help you get the parts to build your own.

Here’s a look at the 7.3L Godzilla in Wolfe’s Foxbody LX Mustang. It’s barely wider than a 351 Windsor, resulting in a ton of mounting options.