It’s safe to say we have all made the decision to skip the truck and trailer in lue of attempting to drive a project car home. We blissfully ignore the tires’ treadwear and date of manufacture, any worn suspension components, or any variety of things that could leave us stranded. This may be a common practice to get home, but obviously, a car should never be in this shape before a track day. In fact, tech inspectors would have a field day observing the condition most of our project cars arrive in, whether it be road course, autocross, or dragstrip. In the case of Project APEX, our 2001 Cobra was in dire need of some TLC to bring it up to street standards, let alone the track.

If you missed the Project APEX introduction, I’ll reiterate that the Project APEX is a well-used 2001 Cobra with 216,000-miles clicked on the odometer. It is far from survivor status, and judging by a variety of faults we’ve already found, it seems that maintenance was not a word commonly used around the previous owners. Thankfully, for our safety, the engine was already blown – which meant there would be no sketchy drive home trying to avoid police or catastrophic failures. We immediately knew we would have to sink some love into the chassis before we installed the engine, let alone jump behind the steering wheel.

Stink Tank

The car sat for an unknown amount of time, so naturally the fuel in the tank had morphed into an unusable varnish that wouldn’t dare be allowed to touch the newly-built engine. Unfortunately, being a 2001 Cobra meant that it was a few years too early to receive the baffled tank that Ford included on the 2003-2004 Cobra. There were two choices at this point: clean up the fuel tank and hope we don’t incur fuel starvation on track, or replace it with a 2003-2004 Mustang Cobra fuel tank. It was a decision that was easily made based on the price to clean a fuel tank and the hazards of dumping a slurry mix of old fuel and chemicals into the local AutoZone’s oil recycling center [Editor’s note: please don’t do that]. Ivan, the car’s owner, was able to score a 2003 Cobra fuel tank for a great price and our nostrils thanked us!

The 2003-2004 Mustang Cobra was lucky enough to receive internal baffles from the factory that prevent fuel slosh when taking corners at speed.

Suspicious Suspension

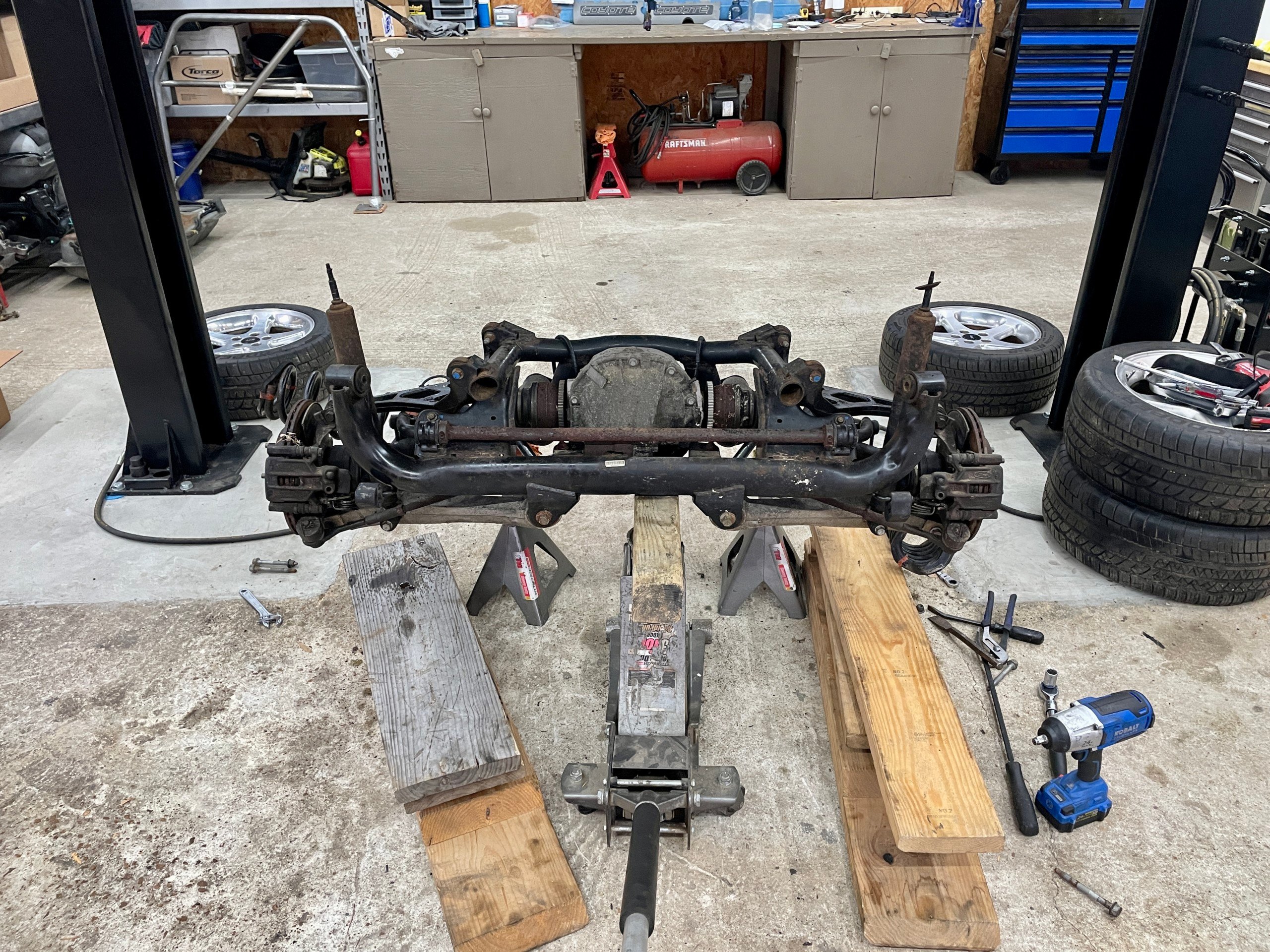

Once the fuel tank was out of the way, the 2001 Cobra independent rear suspension was removed in one piece. Upon inspection, our suspicions were confirmed: the original IRS was very tired and would require major attention to the boots, tie rod ends, end links and more. These products are all easily available, but create a giant time-suck in revitalizing an old suspension section. A 2003 Cobra IRS with low mileage had recently become available and was the perfect time saver. We loaded up in Ivan’s F-100, Project F-Word to go snag the unit up. This new-to-us IRS not only saved time, but also allowed us to start on with a clean platform before installing parts

Our well-used and tired 2001 Cobra IRS dropped out in one piece. This allowed us to build our new 2003 Cobra IRS before lifting it back into the chassis.

When a problem is found on project cars, there is usually another one lurking not far away. In the case of our Cobra, the front suspension was in a similar state as the rear. The ball joints were completely toasted and the struts acted more like a tie rod than the hydraulic damper. In an effort to keep the car close to stock and give the baseline testing a feel for the 2000’s, we decided to install some low-mileage Bilstein struts on all four corners and replace any worn components. We then made a trip to our buddies at D.W.B. Powdercoating to have spindles, front brake calipers and brackets cleaned and coated. This would help avoid corrosion and provide a lifelong durable coat, not to mention make our photography job a lot easier!

Brakes, Not Breaks

Brakes are one of the most crucial components in road racing. If you have a proper braking setup you can shave lap times with later braking zones and avoid the dreaded brake fade throughout a track day. This stopping power is also a huge safety net. Full disclosure: the Cobra will be getting a full roll bar and adequate safety restraints, but we have no desire to test its strengths. The factory calipers were past due for a full rebuild, the rotors looked like a piece of the titanic post-sinking, and our brake pads were questionable for even cruising through the neighborhood. At this point we knew we were going all-in and needed some advice.

We connected with the professionals at Baer Brakes on a rebuild for our front calipers. Baer was able to provide us with the seals, dust covers, banjo bolts, and hardware. The factory lines were prone to swelling after heavy use, so we also snagged a set of Baer’s stainless steel braided brake lines to keep the braking feel firm. We approached the rear calipers with the same energy as the front, but found the E-brake caliper mechanism causing more problems and ultimately deflating our steam. It was then that we discovered Baer sells a complete rear caliper that mirrors the Mustang GT’s rear caliper, and alleviated any more of our time spent trying to rebuild the stock rear calipers.

Rebuilds and rotors. The new braking setup on Project Apex is going have our hearts in our throats.

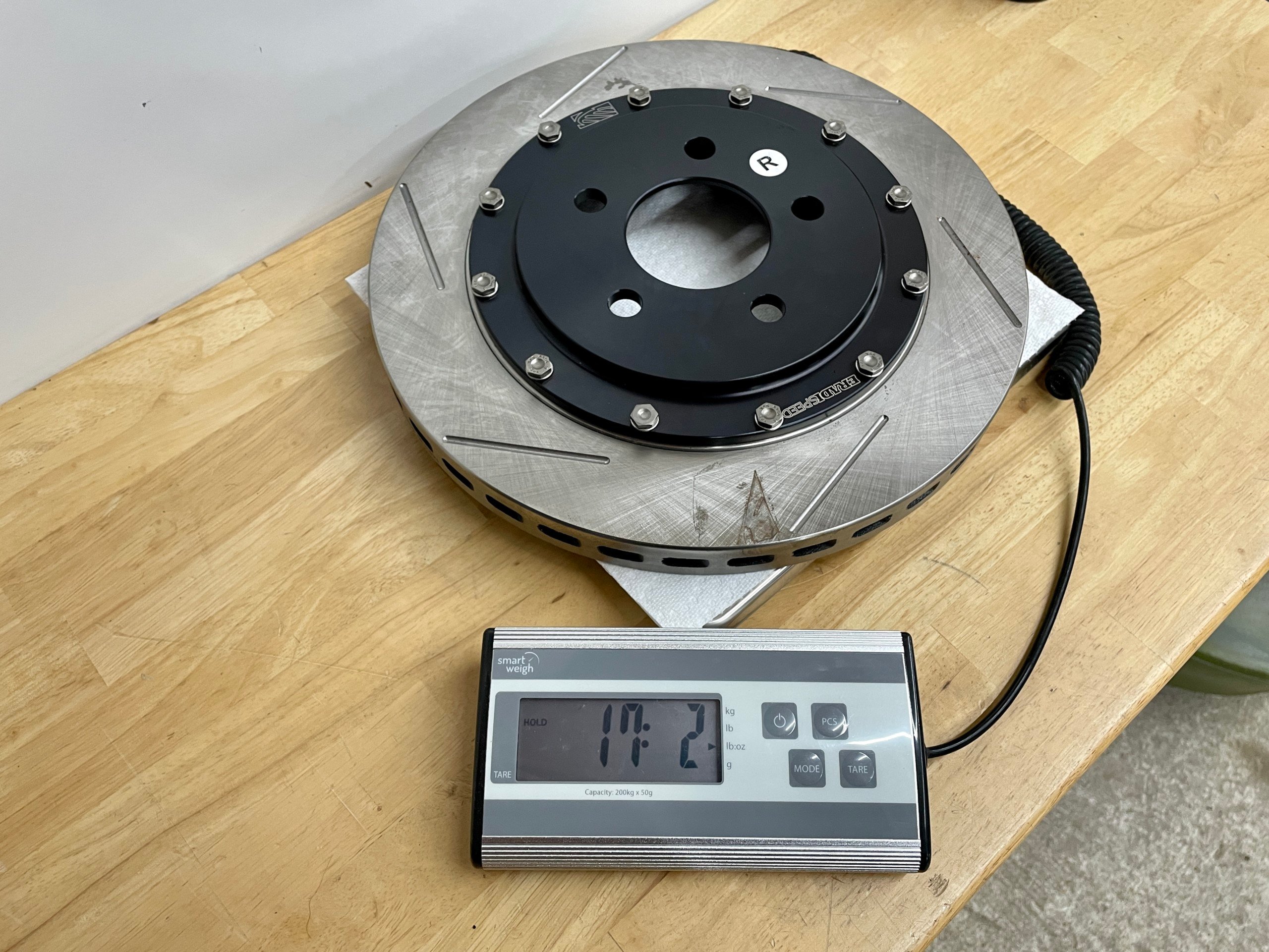

The goal behind the first portion of Project APEX’s baseline testing was to keep it as close to stock as possible, but we did upgrade the rotors to Baer’s EradiSpeed+ two-piece units. The rotors will not only reduce rotational weight, but also dissipate heat quickly through its drilled and slotted design. The last piece of the braking puzzle was to provide the calipers and rotors with a set of track pads that would give us the extra bite when hot, but not wear too quickly. To determine the best brake pad, we contacted the tech department at Steeda Autosports for some recommendations– after all, they’ve been on the track with Mustangs since 1988. They suggested a set of HAWK Black rear brake pads and Hawk HT-10 front brake pads that would provide exactly what we were looking for.

Clean And Cooled

Since we have a fresh engine, we wanted to make sure that any fluid entering it would be clean, as well. We also wanted to make sure our engine could sustain a long life of high-RPM racing for extended amounts of time. While the oil cooler assembly on the Cobra was adequate for its day, its lengthy history of runtime and possible contamination made it a replace-only item. Through a Mustang road race Facebook group we discovered the Road Race 1 oil cooler.

Road Race 1 worked to have a kit manufactured to its specifications and, best of all, its kit works with our four-valve Mach 1 engine. The Road Race 1 oil cooler kit with remote thermostatic filter mount includes pre-assembled lines, heat wrap, hardware, fittings, adaptor plate, multiple gaskets for different OEM configurations, and directly labeled products with instructions for a proper install. What makes this a trick piece is that it has an internal thermostat that bypasses the oil cooler until the oil has reached 180-degrees. At that point the oil is then routed to the oil cooler.

Also on our replacement list was the factory radiator. Once again, 216,000-miles of gunk can produce some gross internals, and the last place we wanted to find that gunk is in our new engine’s coolant passages. We checked Steeda’s website while we were purchasing the brake pads and instantly found a Fluidyne radiator that would be a direct fit for our 2001 Cobra. The new radiator was not only larger in size and provided a larger cooling capacity, but arrived from Steeda within a matter of a few days!

Our Tires Were…Tired

Our final step for preparing the car for a track day was to install a set of wheels and tires. The old tires on the Cobra wheels were done, and showed signs of cracking under the pressure of knowing its lifespan was over. We opted for the classic design of the 2003 Cobra anniversary wheels. The next big decision was to find what rubber would be making up our contact patch. We wanted to showcase what a set of high performance summer tires could do before repelling down the treadwear scale. These tires would need to pull double duty by having a decent life span, but also be able to grip under extremely aggressive cornering. This landed us at the Falken website, and specifically on the Azenis FK510 landing page. These tires will give us exactly what we need for baseline testing and a perfect tire for someone looking to get onto the track without sacrificing tire life.

Properly Prepped

As you can tell we’ve put a focus into making sure our track toy is not only safe, but also performs on an above average level. Tech inspectors don’t mess around with safety, and having to skirt around them is about as silly as not maintaining a vehicle. The coined term “Project Car” is synonymous with problems, but this list should help anyone get their car up to spec for their first track experience. Stick around for the next segment as we get our safety on.