When we originally wrote the plans for our 2020 Shelby GT500 on the dry erase board it had two bullet points: “Make Power” and “Make More Power.” However, after our first outing we learned that we had to take a step back and prepare the suspension first. We were one wheel hop away from disaster, and that’s a predicament we do not wish to partake in. Thankfully, we’ve resolved the chassis issues on our second round with BMR suspension, Forgeline wheels and Mickey Thompson tires. Now we can circle back to our dry erase board for our favorite step, making more power!

Our GT500 already came with a mind-warping 760 crank horsepower from the factory, but for gearheads like ourselves that is just a baseline number. We wanted to increase the horsepower from the start, however, we were going to utilize the K.I.S.S. design principle with our selection of goodies. We decided to keep it simple with products like a ZPE Griptec pulley with tensioner and tool (PN GT265BV2ZA, G6TL17MMST) , Fuel Injector Clinic injectors (PN IS403-1000H), JMS Chip voltage booster (PN P220EZFS20), Ford Performance oil separator (PN M-6766-A52), JLT intake (PN CAI-GT500-20) and a set of Brisk spark plugs (PN RR14S). These products were all designated to be part of this segment based on ease of install and bang for the buck. We also made the decision to switch from California’s pitiful pump 91 to every racers favorite pump performance fuel: E85.

Making More With Less

Before we dive deep into the bolt-on affair we’re having, we wanted to remind everyone that our goal was not to be the fastest GT500 or produce a max-effort build. We didn’t even care to claim one of the numerous micro records available for the taking. We just want to showcase how capable the GT500 is with minimal modifications. This car will continue to be a streetable daily driver that can also fiercely attack the ⅛- or ¼-mile strip. A street and strip brawler cloaked in road racing apparel, albeit the sheep’s clothing has been slightly lifted with the drag pack setup.

Method Before Madness

When it came to choosing parts, we wanted to make sure we had a proper method. The last thing we wanted to do is throw an entire catalog at the engine bay. We knew we had to produce results to quench our power-hungry thirst on a limited parts list. In this round we decided to focus on boost level, intake air, and the fuel needed to support and optimize the increased airflow.

We started off with a smaller sized upper pulley and tensioner before increasing fuel. We knew our fuel pumps would love the additional voltage to maintain strong fuel pressure and flow, so we added a voltage booster. Floating down the fuel stream we found the factory 62-lb injectors insufficient for our new corn-based friend. While some GT500 models came with a factory oil/water separator, ours didn’t. No worries, we were already deep enough to install one. We finished this round off with a large JLT intake. After that it was time to throw some new plugs in and see what numbers our GT500 could conjure up.

Pulley’ed for Success

The 2020 Shelby GT500 finds its forced induction via an Eaton TVS R2650 supercharger. The stock Eaton supercharger came equipped with a 3.085-inch pulley. This supercharger and pulley combination allow it to produce up to 12 psi and helps in attaining that 760 horsepower and 625 lb-ft of torque figure. Everyone knows that more power is just a smaller pulley away on supercharged engines, so naturally that was our route, as well.

The range of pulley companies is about as vast as pulley combos, however, there was a clear cut winner in this case, ZPE. ZPE won our vote with its Griptec machined pulleys: ZPE painstakingly micro-machines each groove to provide maximum grip without damaging the belt. The unique process has proven effective in eliminating even minute belt slip you didn’t know was there. Since our pulley of choice measured 2.65-inches, we needed all the help we could get. Its install tool also aided in the install process and cut down hours of shop time.

To install a new pulley we had to remove the factory snout. We then drained the coolant from the thermostat housing. After that we installed the new hub, pulley and 10 bolts. (NOTE: Don't forget the locktite on the smaller bolts!)

Corn Fed and Amped Up

When making the swap to E85 and raising our power levels, we knew our fuel system was next in line. The lovely corn-based blend burns through roughly 30-percent more fuel than gasoline. This increase in fuel usage also meant our factory 62-lb injectors didn’t stand a chance. Before we gambled on a lean out situation, we swapped in a set of 1000cc Fuel Injector Clinic injectors.

Increasing fuel injector size is more than just selecting a larger cc injector. Since fueling is such a key factor to our beloved internal combustion engines, we had to make sure we were using quality components. Fuel Injector Clinic fit that bill with its high-impedance Bosch core and E85 compatible injectors. Each injector from Fuel Injector Clinic is flow matched and serialized, which combined with their pulse width control, makes tuning a breeze.

We had the remove the hose from on top of the fuel rail to access the 2 fuel rail bolts. Once those were removed we were able to lift the fuel rail out in one piece.

Fuel Pump Voltage Made EZ

Although the GT500 came equipped with dual fuel pumps in the tank, we knew we would be pushing the limits on E85. To avoid replacing pumps, hanger, and wiring, we opted for the tried and true method: a voltage booster. Factory ECU monitoring has come a long way and fuel pump voltage boosters have followed suit. The latest voltage booster to hit the market was the JMS Chip FuelMAX EZ.

We decided to use the FuelMAX EZ because it uses the GT500’s factory fuel pump controller signal to increase pump voltage as needed. This means it automatically increases pump voltage in real time up to 22v and varies the voltage supplied based on demand, rather than peak voltage at all times. The five minute plug-and-play action relieves any hacking into the factory harness and made our decision even more just.

We had to remove a few items to get to it, but the GT500 fuel pump module is in the trunk. Once found, we plugged the JMS Chip FuelMAX EZ in. We then secured the ground wire and mounted the FuelMAX EZ module. Once installed the FuelMAX EZ is completely out of sight and out of mind.

Gotta Keep them Separated

While owners of the GT500 carbon-fiber track package or handling package enjoy the spoils of a factory installed Ford Performance oil separator, the rest of us mere mortals have to purchase it separately. Thankfully, Ford Performance offers the same part number as a complete kit – this ensures fitment will be on point and not an afterthought filled with complex DIY engineering.

The purpose of the Ford Performance oil separator is to prevent oil vapor from entering the intake system or inevitably finding a new home in our intercooler. Even though this is considered a performance modification, all GT500 owners could see the benefits of an oil separator installed. Since we were pushing past the factory power levels we thought it was time to address this. Aside from being a quality kit that serves its purpose, it also includes a drain back to the valve cover, which makes it essentially maintenance-free and removes the messy oil tank draining process.

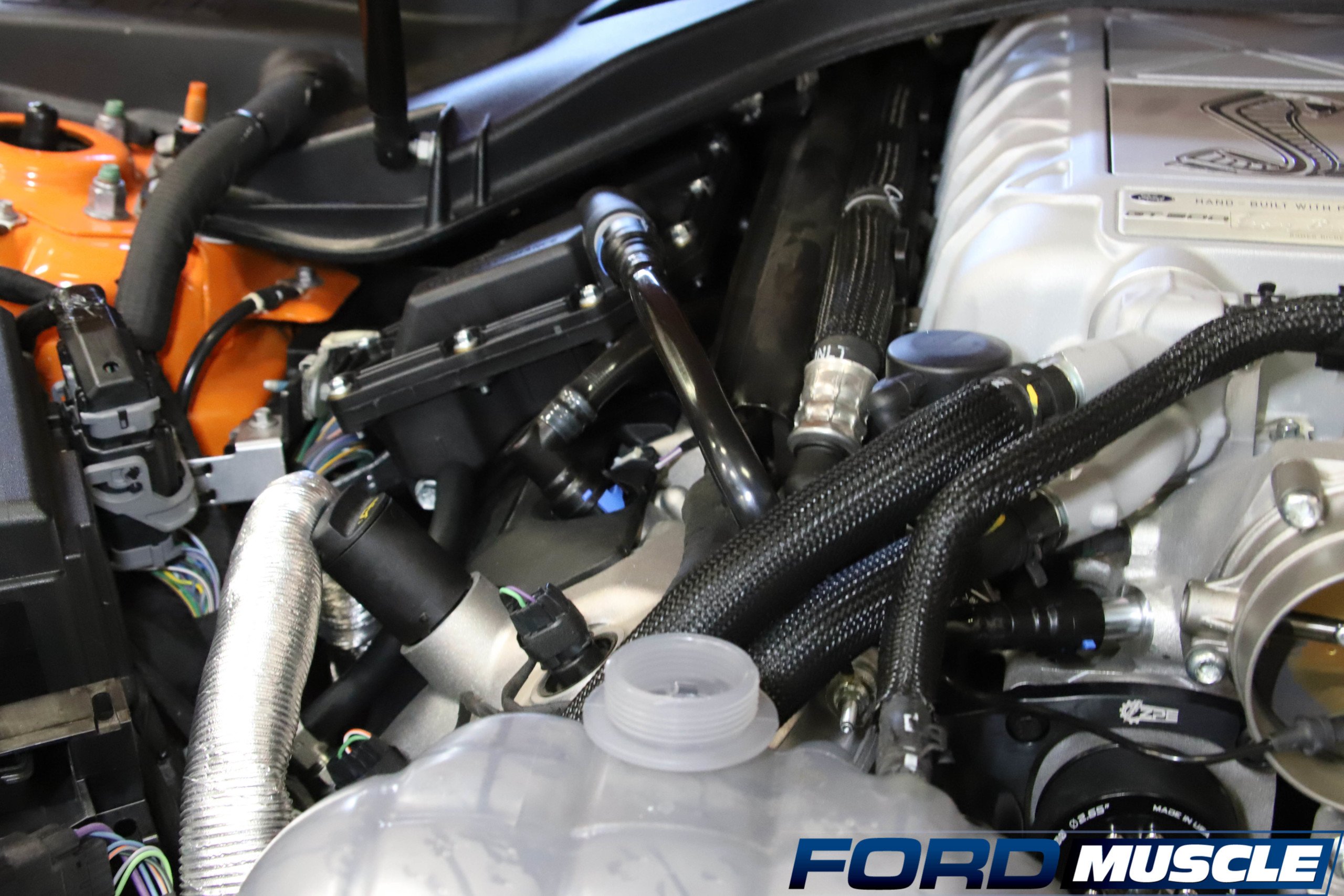

To install the Ford Performance oil separator, we had to cut and remove the wiring harness retention straps and unplug coil number 2 and 3 connector. We then positioned the bracket under strut tower brace and wiring harness. The bracket then installs onto the 3 cam cover studs. After that we removed the PCV and PCV breather hose from the passenger side engine cam cover. We then Installed Cam Cover vent tube supplied from the kit. After this we were able to mate the oil separator to the bracket and connect the hoses.

Bring Forth Thy Air!

There is one thing our Predator engine craves as much as fuel, and that’s intake air volume. This is why we chose the JLT Big Air intake. The JLT Big Air intake is one of the largest on the market going from 6-inches at the filter and tapering down to 4.5-inches near the throttle body. The air box portion consists of heatshield side walls and utilizes the underside of the hood to pose as the lid.

While JLT doesn’t notate it as a cold air intake, it sure took a lot of preventative measures to keep intake air temperature down. The roto-molded plastic acts like a thermal insulator, which protects the filter from sucking in hot engine bay air at idle and low RPM. When the car is in motion, the grille air inlets produce a ram-air effect that pushes air into the JLT specified S&B filter.

We removed the stock air intake assembly, IAT sensor, and PCV connection. We reused the rubber mounting grommet and metal insert from the stock air box on the JLT heat shield. The heat shield was installed along with the filter. We then installed the intake pipe, rubber reduce for IAT sensor and clamps. We tightened down the clamps and we were ready to rock.

Verifying Spark

After we addressed our boost level, fuel, and air, it was time to put a fresh set of plugs in before dyno tuning. We opted for a set of Brisk Racing RR14S spark plugs for optimal spark on our GT500. The RR14S is a non-projected tip that does well with nitrous or forced induction. Where we lack in laughing gas, we make up for in boost!

Hitting The Rollers

As with most manufacturers, the horsepower figures given are almost always measured at the crank. However, our real life baseline dyno showed the 2020 GT500 making 674 horsepower and 561 lb-ft of torque at the rear wheels. We knew, or at least hoped, we would be surpassing those numbers. After all, countless hours were spent on the bench dyno wearing the buttons of our TI-83+ thin. We enlisted the help of tuning wizard Lund Racing to squeak out the most power possible.

In previous years, tuning could be an all day process, but once again technology prevailed and tuning was the simplest part of the entire mission. The flashing and logging of the system was extremely straightforward on the dyno and it only took three revisions before everyone was perfectly happy. Our numbers after this bolt-on affair triggered the dyno ticker to 828 horsepower and 666 lb-ft of pure evil torque, for an increase of 154 horsepower and 105 lb-ft of torque.

Verdict

The days of a modification list taking three scrolls of a mouse to see a 600 horsepower build are gone. The same can be said about all-day dyno tuning. The GT500 is so advanced that it only takes a few simple modifications to knock down a 150-plus horsepower gain. Join us next time as we push the limits past the bolt-on stage and really dig into our GT500’s potential.