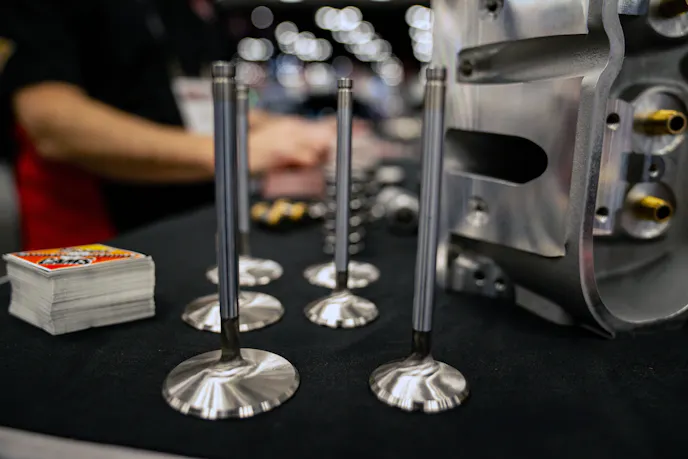

If you are trying to make a race engine scream at high rpm, you eventually hit a wall where physics starts fighting back. That wall is usually valvetrain weight. At the PRI Show this year, PBM offered a way to knock that wall down with their new line of titanium valves. We stopped by the company’s booth to chat with Jack MacInnis about why a company known for solid, reliable cylinder head components is diving into the world of exotic materials.

The conversation immediately turned to the enemies of high-speed reliability: mass and inertia. When you are forcing an engine to spin at aggressive speeds, a standard stainless valve becomes a liability. It requires massive spring pressure to keep it under control, and even then, you risk valve float.

“They’re very light, and that weight savings is critical in high-rpm engines,” MacInnis said.

By switching to titanium valves, you aren’t just shedding grams; you are fundamentally changing the dynamics of the valvetrain. Less weight on the valve side means the springs don’t have to work as hard to snap the valve shut, and the valve seats don’t get hammered as violently on every closing event.

These aren’t for your Saturday night cruiser or a street/strip car that sees thousands of highway miles. Titanium is a race-only metal designed for competition engines that live their lives at the top of the tachometer. PBM is rolling these out specifically for its own race-spec cylinder heads, with fitments for big- and small-block Chevys, plus select Ford applications.

While PBM had the stainless game covered for general performance, offering titanium valves closes the gap for serious engine builders who need that extra edge. It ensures that when you buy a high-end casting from them, you have the supporting hardware to make the most of it.

You might also like

Project Fox Dreams Gets An Exterior Glow-Up From LMR

Our limited-edition 1993 Mustang LX convertible suffers from aging. We refreshed its exterior with a new top and exterior trim from LMR.