Now that the shop is coming along, although I’m certainly not done setting it up, I wanted to get the Boss 9 project underway again.

I want to take this time to introduce a good friend and key “helper”, Steve Ortiz. Steve is such a help to me. He owns several vintage mustangs. In the pictures he’s the good looking one with the moustache. I’m the old, balding fat guy.

I gave the car a name: The Boss 529 Shotgun. Some explanation is in order. First, all car’s derived from projects seem to get a name. The 529 comes from the final engine cu. in. The Boss 429 heads, valve covers and high rise intake manifold, from Jon Kaase racing, are mounted to a BBF 460. With the bored out cylinders and forged steel stroker crank, I ended up with 529 cu in engine. More on the engine build later, but the engine goes to the dyno this Friday, May 6th and I plan to pick it up end of May, early June 2011….. certainly, a major milestone will be reached. The “shotgun” tag came from the early days of the Boss 429 Hemi engine development. Here’s a very good link for a brief background on how the Boss 429 hemi came to be… https://www.nzmustang.com/history/boss429.htm

The “Game Plan”:

– Complete the striping of the car to a bare shell

– Get the car mounted to the rotisserie

– Fit metal that needs replaced

– Mount and install all new components

– Get car to a complete rolling chassis

– Complete disassemble, i.e., strip again

– Paint and powder coat

– Rebuild to complete the Boss 528 Shotgun.

As we removed the interior we were very pleased to see that most metal components were in good shape. Most early Mustangs have lost of rust through in the cowl area, firewall, floor pans and trunk area. In general, only the floor pans need replacement. However, I’ve decided to replace both front fenders and doors even though they look fine…. So why am I’m doing that? My concern is what I can’t see. For example… under the undercoating and in the seams, is surface rust. I don’t want to put all this time and effort, new paint and then in a few years the rust shows up. The cost of 2 fenders and doors is not that significant so I just replace them. The trunk aprons also need replaced.

See more on page 2…

Next… to the lift to mount the car on the ROTO 2000 rotisserie

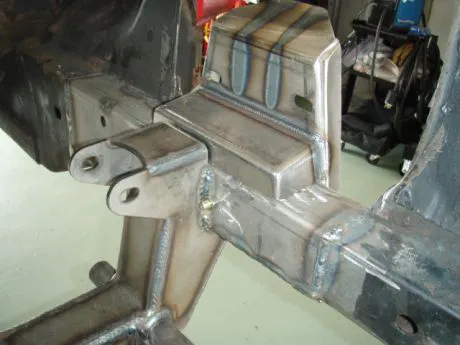

Once the car was all secure to the rotisserie…. We’re ready to start the new front suspension from Total Cost Involved. We first had to cutout the factory shock towers, sway bar mounts and the strut rod mounts. I will say this, being able to rotate the car 360 degrees is a wonderful thing!! I first did a complete power wash with a 3600 psi pressure washer.

Now that the cleanup and grinding is complete, the installing of the front frame rail boxing plates are next, followed by the cross member, coilover shock towers and sway bar mounts. I plan to do much more reinforcement… more on that later. I want to note, before welding anything, I removed the floor plan over the frame rails/pan support to verify what we thought…. i.e., to be free of corrosion. They were absolutely clean and free of rust; what a relief!!

See more on page 3…

Now, on to the sheet metal. Stay tuned.

Mark

You might also like

PRI 2025: HPT’s Dual-Entry Turbos Package Easier And Spool Faster

HPT debuted an innovative dual-entry turbocharger at the PRI Show. These units are designed to reduce back pressure and hasten spooling.