Sequential gearboxes were once an item reserved for the ultra-exotic and specialized of the high performance vehicles. Race cars from LeMans to Dakar and everywhere in between have benefited form the quick shifting and simple operation of ‘crash boxes.

The allure of these ratcheting gear changers has sept it’s way into the aftermarket by way of OEM options like the DSG from Audi and VW, and competitor equivalents from Ford, Mitsubishi, and the like.

Sequential gearboxes have often suffered from a perception of fragility when it comes to power and torque numbers. Dog-rings and other components suffer from wear and can be subject to breakage under extreme and repeated loads.

Drifting around the performance eye-candy of PRI we stumbled across the gorgeous creations of Pfitzner Performance Gearboxes. PPG crafts sequential conversions for the performance aftermarket catering to both trackday, rally, time attack, road race, and street applications.

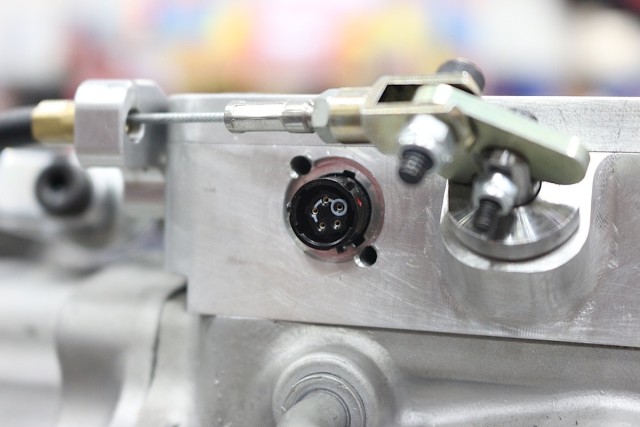

We spoke to the articulate and discerning David Gammon of PPG about their enticing offerings. “We take standard OEM gearboxes — and either redesign them to H-pattern ‘dog’ or five or six-speed sequential. They are fully integrated and supported with the latest blade-sensors which gives us the unique advantage of knowing exactly where the dog position is.” explained Gammon.

In terms of applications, Gammon mentioned that the Australian-produced gear stacks are commonly applied in time attack vehicles but are completely streetable. Their most attractive and ubiquitous kit include their Subaru WRX, Tremec T56, and DSG conversion kits. The ability to retain a mostly stock transmission case but upgrade to a full sequential presents an enticing opportunity to speed freaks across motoring demographics.

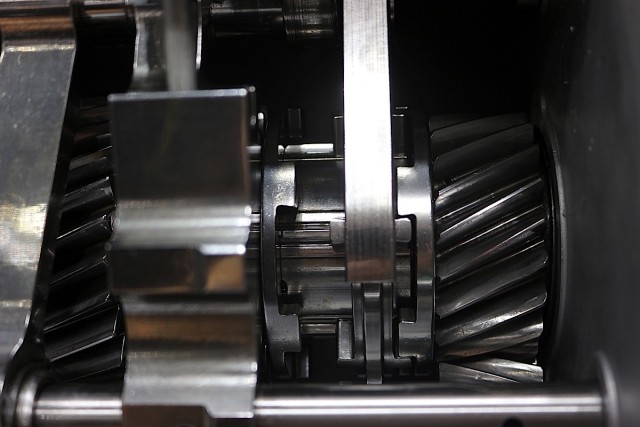

Concerning the construction of the internal components we inquired as tot materials and received a delightfully uncompromising answer; “300M is too generic a term, when you get 300M usually it doesn’t meet specific conformity standards. We only use specific European-supplied steels that are proven, reliable, and robust.” explained Gammon.

Concerning the construction of the internal components we inquired as tot materials and received a delightfully uncompromising answer; “300M is too generic a term, when you get 300M usually it doesn’t meet specific conformity standards. We only use specific European-supplied steels that are proven, reliable, and robust.” explained Gammon.

While to the casual observer, PPG’s standards may be borderline elitist they have a point — there was a time in recent years when Chinese-produced, faux-300M flooded the market, diluting the actual boutique alloy supplies.

“We have a different outlook, in terms what we’re trying to gain from a design, and the gears in terms of hardness and malleability and that’s what puts us ahead.” declared Gammon. PPG is a unique contributor to the power transfer market, and offers a glimmer of what may come for major mechanical modifications.

We were excited to find such a turn-key sequential conversion for cars as mainstream as the WRX, or American muscle running a T56 and hope to see PPG branch into other accessible markets beyond the supercar. With the explosion of high-end builds across import and domestic subcultures, there is no doubt a market for conversions such as these.