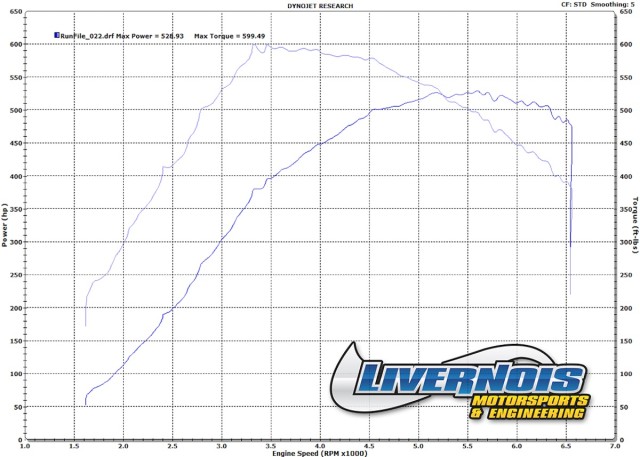

Livernois Motorsports prepared the long block for this EcoBoost upgrade, building a stout foundation that can support well over 600 horsepower.

This engine is built to handle the boost capable of those turbos. — Mike Schropp, Livernois Motorsports

“This engine is built to handle the boost capable of those turbos,” says Mike Schropp, engine department supervisor at Livernois. “In this case the limiting factor is the fuel system.”

The EcoBoost was designed with direct injection, which relies on a mechanical fuel pump integrated into the engine.

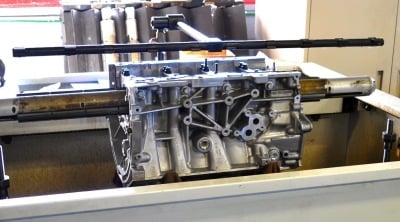

Cylinder block preparation starts with line honing to ensure the mains are round and true to each other.

“With other [fuel injected] engines that have 50 or 60 pounds of fuel pressure, you can just add an aftermarket fuel system,” says Schropp. “These engines run over 2,100 psi. There’s no way to augment the pump.”

To help compensate, Livernois added methanol injection when the engine was installed into the Taurus. This is a stand-alone fuel upgrade that pumps high-octane methanol into the intake under full boost and wide-open-throttle to add needed fuel when the DI system is maxed out. Basically, the kit consists of a remote reservoir for the fuel, an electric pump, a controller and a spray nozzle that is mounted in the intake system.

“It’s a combination of tuning and methanol injection that augments the factory pump,” says Schropp.

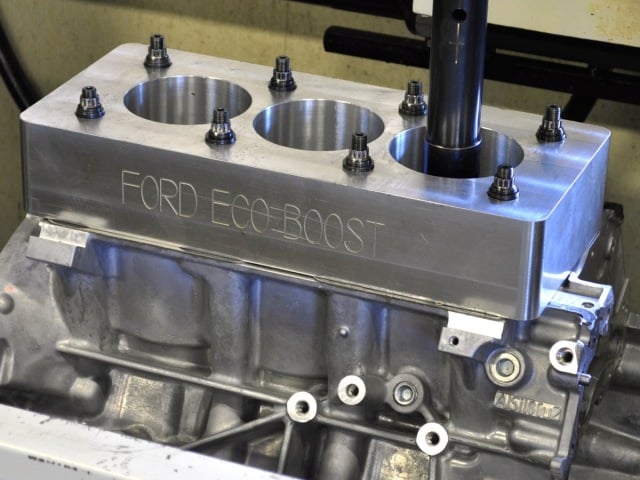

The EcoBoost block is an open-deck design. Livernois machines the deck to accept a billet plate to stiffen the block. Coolant passages are then machined and drilled into the insert.

Strong Foundation

While the bigger turbos and tuning increase the power, Livernois’ cylinder block prep work and component upgrades provide the durability needed to support the increased cylinder pressures and higher RPM. Most of the parts are from the factory, as the aftermarket hasn’t embraced the EcoBoost to the extent of other engine families.

Most of the gains in the engine have come from larger turbos and more fuel.–Mike Schropp, Livernois Motorsports

Early machine work includes align-honing the mains to ensure main clearances and that the bores and round and true to each other. Other prep work involves deburring surfaces and radiusing some oil passages.

Reinforcing the block is achieved with a trick deck plate that is pressed into the stock block. The EcoBoost features an open-deck design where the spaces between cylinder bores and water jackets are left open. Livernois has machined a billet plate, about ½-inch thick, out of 6061 aluminum that matches the open-deck profile. The block is then machined to accept the plate with exact tolerances for the press-fit installation. Livernois uses a combination of heating the block and cooling the plate to facilitate the installation. Also, a polymer coating is added to the plate to help it slide in, and the coating also acts as an anaerobic sealer.

“Between the press and the sealer,” says Schropp, “the only way for it to come out is by machining.”

Getting Ready For Assembly

Once the deck plate is installed, it is surfaced and then machined to provide coolant passages. Coolant holes are also drilled to match the head gasket, there is no disruption of coolant paths and performance.

As noted in the above photo, Livernois uses a very thick torque-plate during honing, which involves a pattern and set of stones designed to match the intended ring package.

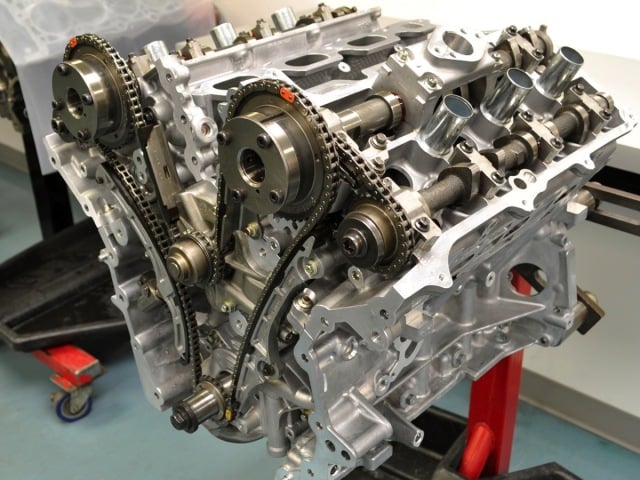

Livernois uses proprietary main and head studs in the engine. The crankshaft is stock with a mild oiling improvement.

“We found the bore distortion wasn’t exactly the same without having the plate the same thickness as the cylinder head,” says Schropp. “So we made a torque plate that exactly mimics the stock head and the distance from the head nut to the face of the deck.”

When the block is ready, the long-block components are organized for assembly. Livernois retains the stock crankshaft but adds its proprietary rod-piston combination.

“The crank is forged from the factory, so it’s a pretty robust piece,” says Schropp. “We just clean it up and modify the oiling a little.”

Lighter, Stronger Rotating Assembly

The pistons are custom made to Livernois specs for use in a turbo engine. Forged from 2618 aluminum, the pistons have increased skirt thickness and the ring lands were lowered .320-inch below the crown to increase the strength of the piston deck. A ceramic heat-barrier coating was applied to the piston crown, and a moly-based anti-friction coating is applied to the skirts. The 1.5/1.5/3.0 ring package features a steel top ring and Napier second. Finally, the piston-pin wall thickness is increased.

Livernois has a custom rod-piston combo made for the EcoBoost V6. Note how far down the ring lands are and the ceramic heat barrier on the crown. Right photo shows the coated bearings and ARP 2000 bolts.

“A big thing with the EcoBoost is direct injection,” says Schropp. “The piston crown has features that mirror the stock piston. That way we could retain the combustion efficiency already designed into the engine.”

The I-beam connecting rod is forged from 4340 steel and fitted with ARP 2000 3/8-inch bolts.

“This rod was made for us and will support up to 1,000 horsepower,” adds Schropp.

Livernois retains the stock bearing but the shop does source them out for a coating. Overall the rod-piston package is just shy of 1,000 grams.

“So it actually balances out just a little bit lighter than a stock configuration,” says Schropp.

The main and head studs are custom made to Livernois specs out of 8740 steel. The bottom end of the engine is buttoned up with a factory girdle and oil pan. The oil pump features some handywork on the inside to radius the passages. The gears are also surface treated for added strength.

Big Power With Stock Cams

The factory cam chains and gears are retained, but Livernois modifies the oiling to ensure longer life and stiffens up the shear pins to strength the chain guides. The cam phasers and camshafts are also carry over from the base SHO engine.

Turbo Upgrade

Providing the additional boost is a pair of larger ATP turbos. The stock turbochargers have a 40mm wheel inducer and 34.5mm wheel exducer on the turbine side and 36.3mm inducer and 49mm exducer on the compressor side. The ATP Garrett upgrades measure 50mm and 43.5mm, respectively, on the turbine and 43.4mm and 56mm on the compressor. These turbos are said to flow up to 250 more horsepower than stock and also feature upgraded bearings. ATP does customize these turbos to meet Livernois specs, such as altering the wastegates to meet the shop’s needs.

Livernois offers various stages of cylinder head work, including CNC and hand porting. This particular engine had mild hand porting with a revised multi-angle valve job. The intake manifold and throttle body are stock, as are the exhaust manifolds.

“The cast-iron manifolds are very robust. Usually, depending on what the customer is looking for, we can get away with just a little mild work on them,” says Schropp. “There’s more of a restriction from the downpipe to the exhaust. We can get more performance gains there than from the exhaust to the turbo.”

Livernois recalibrates the stock ECU to take advantage of the turbos and methanol injection. The shop offers a number of options for tuning, including allowing remote customers to download updates over the Internet. Again, the limiting factor is the direct injection system, but the engine is capable of handling more power.

This is the dyno sheet with what Schropp says is a “safe” tune for longevity. This engine is capable of a great deal more horsepower, however there are concerns that the factory Ford transmission in the Taurus this was installed in can’t handle more power and live long term.

“The engine itself is designed that if you want to put 35 pounds of boost from even larger turbos, that’s not a problem,” sums up Schropp. “It’s getting enough fuel to go along with that boost.”

600 hp at the crank puts the SHO squarely into the same category as some of the world’s most exclusive luxury sedans. It also makes it a quietly menacing threat on the street, or any track, giving the SHO a truly sleeper quality. Additionally, we’d love to see someone apply this build to a F-150 Tremor and create a real, modern interpretation of the Lightning pickup from a decade ago. Regardless of the application, Livernois is proving that the 3.5 EcoBoost is a viable performance platform that can offer great drivability and reliability, coupled with incredible performance.