Employing a racing seat is a “must” in any vehicle that will be turning corners hard. Most racing associations mandate the use of one-piece competition seats; others strongly recommend it. And for good reason, as racing seats are designed to provide driver protection and keep him or her firmly in place in spite of immense lateral G-forces. Face it, you can’t do a good job of controlling a car when you’re sliding all over the place. Snug is good!

On the upper end of the spectrum are full-containment racing seats, with those carrying SFI 39.2 or FIA 8862-2009 certification meeting rigorous lab tests and proven worthy of providing driver protection under the most demanding conditions. Given all the hoops the manufacturers have to jump through, SFI/FIA seats are also more expensive than others.

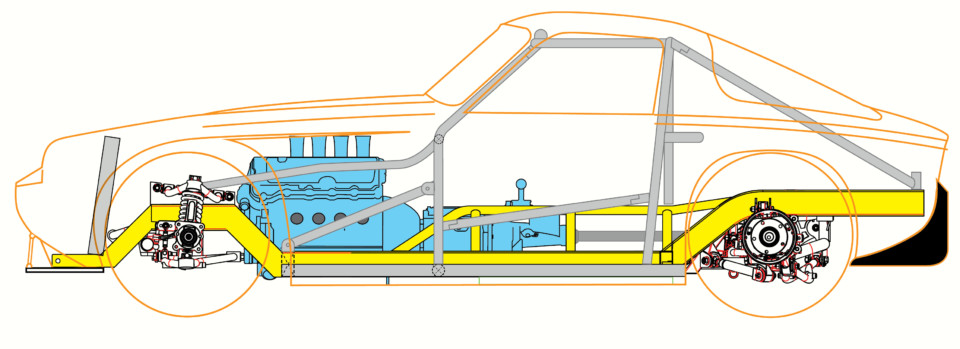

A rendering of the chassis in T-Rex gives you an idea of the challenges to properly mount a racing seat.

For many applications low-back aluminum seats are the preferred replacement for OEM adjustable buckets. They’re lighter, provide excellent lateral containment, and the snap-on covers make for ease of maintenance. Unlike their tall-backed brethren, they don’t provide head protection — a padded headrest is essential for competition. A number of racing associations require a minimum 36-square-inch headrest with high-density padding — SFI 45.2 spec material is required by some. This follows along with the requirement for rollbar padding.

While the rules for installing rollbars, seatbelts, and harnesses are pretty explicit, there’s a whole lot of grey area when it comes to anchoring seats. Double that when you’re dealing with a fiberglass-bodied car. Common sense must prevail.

Obviously, the seats must be anchored in such a manner as to cope with front, rear, and side-impact situations. Additionally, you need to factor in what can happen in a roll-over, where centrifugal forces want to literally tear the seat out of its mounting.

Faced with the need to install compact seats in “T-Rex,” a 1974 TVR restomod destined to be campaigned in SCCA Solo, Goodguys Autocross, and USCA Optima Ultimate Street Car competition, among other events, a pair of Kirkey Vintage Class Bucket (style 41V) seats fit the bill perfectly.

The Kirkey 41-V aluminum seats are nestled between the steel frame and rollcage of T-Rex. The seat mounting brackets secure to a tubular crossmember in front and steel plates sandwiched in the fiberglass in the rear; back braces are secured to the roll cage back-brace.

To provide ample seat adjustability, Kirkey’s #99204 Side-Mount Brackets were employed, with some extra holes drilled on the base for some fore/aft relocation if needed. As you might imagine, properly securing the brackets to the floor is of critical importance.

Given that the TVR’s fiberglass floor has a drop in it for the seat, it was possible to fabricate a brace made of 1-1/4 x .120-inch-wall steel tubing between the 2 x 4-inch main framerail and the tubular steel body outrigger. The front of the Kirkey bracket attaches to inserts welded to the brace, while the rear is secured to 2 x 4-inch steel plates that are sandwiched in the fiberglass, with large area washers used for good measure. The front brace also makes for a great mount for anti-submarine straps used in 5-point or 6-point harnesses to loop around.

Steel plates are sandwiched into the fiberglass floor to provide secure anchoring for the seat. A large-diameter washer will be employed underneath the floorboard. The front of the seat attaches to the tubular steel brace.

While some racing associations call for 5/16-inch diameter Grade 5 or Grade 8 bolts (or 8mm with ISO 8.8 rating), ARP polished stainless steel bolts were used in T-Rex. With a 180,000 psi rating they’re far superior to Grade 8 or ISO 10.9 (150,000 psi) and are impervious to rust, etc.

Premium-grade ARP polished stainless steel bolts were employed. At 180,000 psi tensile strength they’re 20 precent stronger than Grade 8 and impervious to rust, etc. ARP also makes special heavy-duty, large-diameter washers.

Properly bracing the seat-back is also very important. Kirkey makes a bracket that matches the contour of the seat and can be secured in several ways — the key being to use multiple fasteners and spread the load out as much as possible. Because of the proximity of T-Rex’s seat to the rollcage, some special tabs were made.

Here’s a rear view of the head rest showing its adjustability, and rollbar back-brace mount, as well as the adjustable mounts that secure the Kirkey rear seat brace. Car is a Vintage D/Production 1962 Daimler SP250.

That said, the folks behind T-Rex, Penta Motorsports, also did a similar installation of a Kirkey 41V in a D/Production 1962 Daimler SP250 and had ample room to employ the #99212 brace via an adjustable arm attached to the rollbar back-brace. The seat brackets are attached to an aluminum plate, with the fiberglass sandwiched by steel straps.

When employing low-back vintage-style seats, most sanctioning organizations require headrests. This 6 x 6-inch padded unit complies with the regulations.

Sports cars aren’t the only vehicles that combine aluminum seats with fiberglass bodies. In addition to purpose-built racing seats, a popular mod among street rodders is employing “Bomber” seats. They’re light, compact, and can be finished to suit the style of the build.

Done right, aluminum seats and fiberglass cars are an excellent pairing.

Aluminum seats can work well in fiberglass-bodied street rods too. Here are a pair of Speedway Motors “bomber” seats in “23-GT” — an award-winning track roadster built to go around corners.