When it comes to Blue Oval performance in stock car racing, there have been several generations of superb powerplants to grace the NASCAR tracks over the past few decades. No one knows the Ford Yates C3, D3, and FR9 engines better than the family of companies with “Roush” in the name. Mitchell Stapelton (the namesake of the Stapelton42 YouTube channel) headed to RFK Racing (formerly Roush Racing) and got the full rundown on the different generations of engine architecture from Jeff Clark, the Executive Vice President of Roush Yates Engines.

Standardizing The Blue Oval

“Robert Yates was well known for the power he was making and NASCAR approached him to create consistency with all Ford teams,” Clark explains. “They wanted him to share his designs, so that they could make a template for all of the Ford cylinder heads going forward.” That was unheard of at the time, with Lake Speed, Sr. saying that when he ran a Chevrolet, he couldn’t even buy a raw casting, because he wasn’t one of the top dogs. This new program would make top-level Blue Oval parts available to the entire field.

Before the C3’s debut, there were all sorts of engine combinations showing up in the pits. “People had intake ports that were round or square or rectangular. The same for the exhaust ports,” says Clark. “Robert [Yates’] program got everyone on the same page as far as intake and exhaust ports, and valve angles — because NASCAR wanted that mandated — as well as combustion chamber size. Then he was tasked with creating cylinder heads for all of the Ford teams.” This spawned the term “Yates Head.”

The Yates C3 was the first of the modern purpose-built Blue Oval NASCAR engines. While there had previously been A302 and B302 heads, the Yates C3 used a modern non-production R452 block and highly specialized heads that started as C302 castings before being worked over by Yates.

1990s — The C3 Era

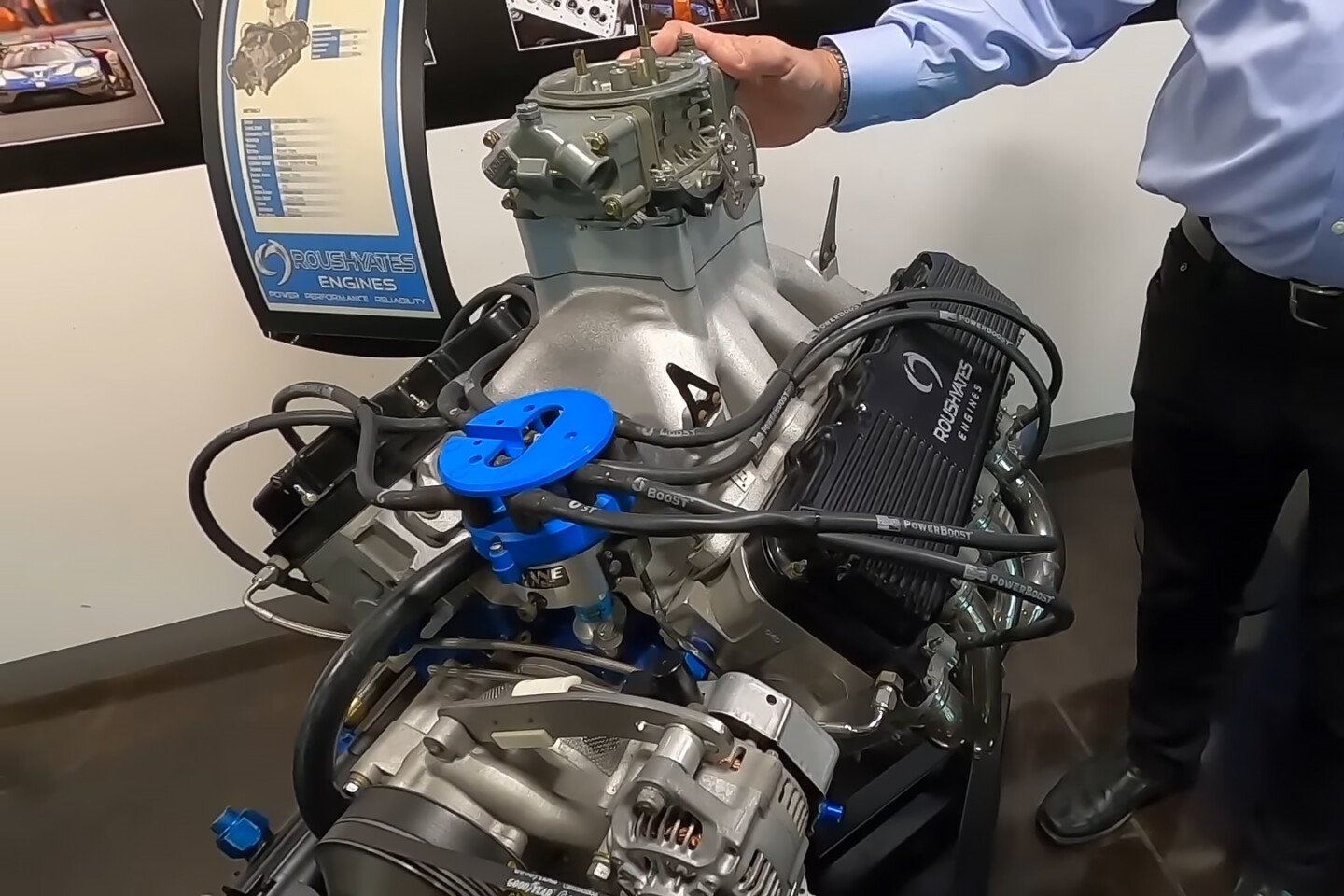

“[The C3 engine] was very powerful for what it was. If you look at the whole engine, there was a lot of early development on it, like water coming out of the cylinder heads, and water coming into the pump before being pushed through the block. It was really neat how the water would flow in this engine.” Besides innovative fluid routing and great cylinder head flow, the C3 started to innovate below the deck as well.

“The engine block used is a hybrid Windsor block,” says Clark. “We call the C3 block the R452, which was the code name from Ford. It had both Windsor and Cleveland design features. It had Windsor bore centers and Cleveland oil and water passages. They took the best components and designs, incorporated them into one, and submitted it to NASCAR. Before the R452 racers were using a Windsor or a Cleveland block straight out of the junkyard.”

One of the large differences over production heads were the exhaust port extensions, which helped get the gasses away from the valve more efficiently.

Starting with a Ford C302 head, Yates would work the castings over to within an inch of their life to create the Yates C3 head. “The castings would come in with porosity and cracking issues. The casting would be pressure tested before being welded up and changing the ports and valve angles. There was a lot of hand-grinding in the early days,” Clark says.

The C3 existed in a time of pretty serious technological revolution, seeing the introduction of CNC machines, capable of exactly replicating a port design, as well as rapidly improving designs. Those iterations of the C3 ultimately led to the introduction of the next generation of the Yates engine.

New Design For The New Millenium — Enter The Yates D3

Ford wasn’t the only company developing engines at the time, and the Blue Oval-Bow Tie rivalry was in full effect. “We were on track with the D3 in 1998. [Chevrolet’s] SB2 was out there about the same time, as was doing really well,” recalls Clark. They say that competition breeds innovation, and that is apparent in both the D3 and its subsequent replacement, the FR9.

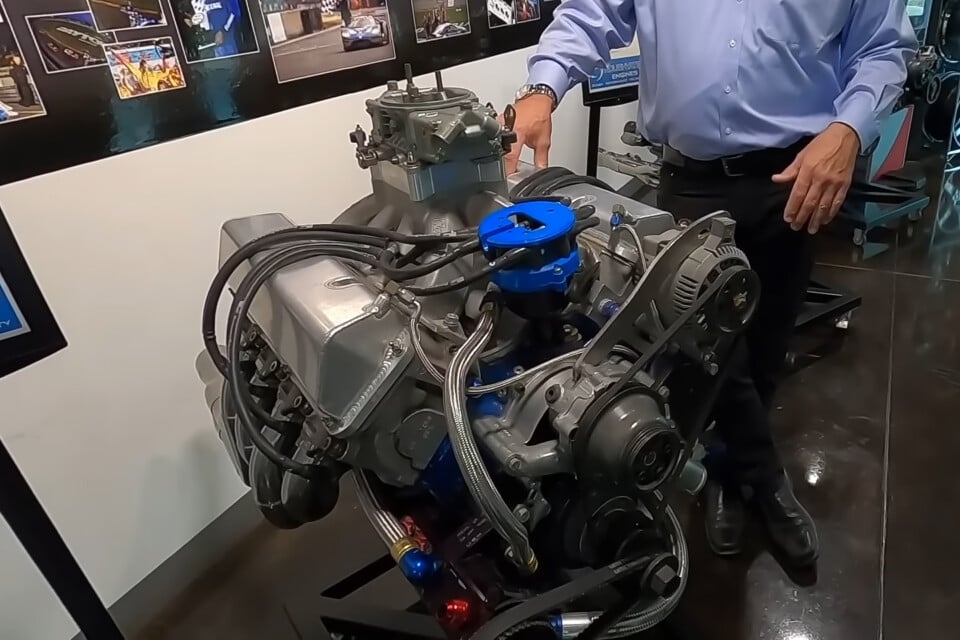

“The D3 had a higher port location than the C3,” says Clark. “That allowed for a much more direct line of sight path to the valve. The other big change was the block. It went from just cast iron to compacted graphite iron (CGI). By mixing graphite into the iron, you get two things: it had a better thermal transfer coefficient so it could get heat out of the block faster, and it made the engine lighter. There was about a 40-percent reduction in weight with CGI.”

While the block of the D3 engines looked similar to the C3 — they used the same design — it was made from compacted graphite iron, or CGI, which allowed the block to be stiffer, stronger, and lighter.

The block-casting molds were the same between the two generations. Both had side-mounted engine mounts like you would find on a production engine, but apart from that, there wasn’t much “production” about either R452 casting. The D3’s CGI material was the large change below the deck. Above the deck was where the major generational changes were.

“The D3 heads themselves were massive,” says Clark. “More aluminum makes for more of a heat sink as well as allowed for more water flow as well. Plus the new exhaust port height being raised .200 inch was a real advantage [over the C3] in power.” The intake manifolds started to grow in the D3, aiming to get closer to equal-length runners and even distribution from the large carburetors still being used at the time. All that added up to “almost 900 horsepower out of a 358 cubic-inch engine.” The later D3 engines were the first to see segmented oil pans as opposed to the single large “shoebox style” pans.

The real differences in the D3 were in the massive heads. Besides larger ports, the larger mass of aluminum served as a heat sink, as well as allowed for larger cooling passages.

FR9 – The Next Generation Small-Block

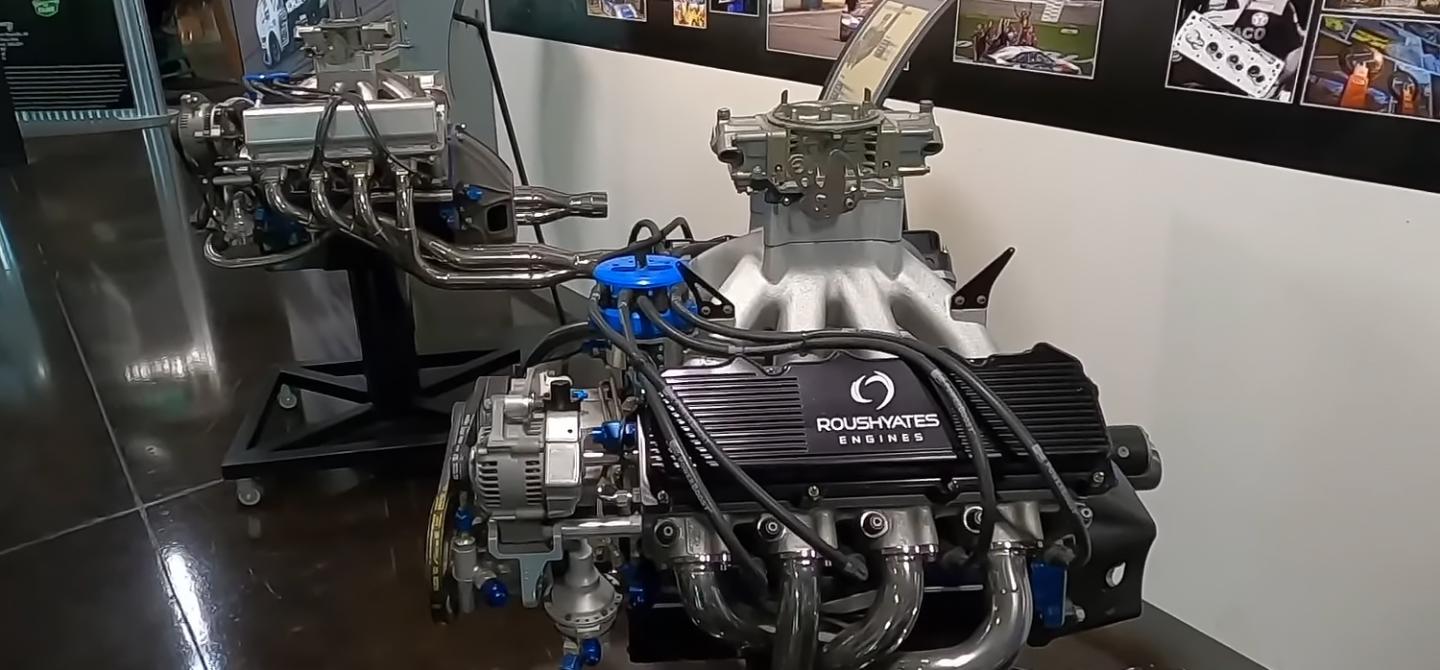

The FR9 engine, as the name suggests, debuted in 2009, and was a clean-sheet design. While it might share some of the features of the late D3 engines, none of the parts are interchangeable. Where the C3 had externally fed valve spring oilers, and the D3 had valve spring and piston oiling, the FR9 also has both, but with the oil carried internally, through integrated oil passages in the block and head as opposed to external feed lines.

The FR9 was also the first generation of Blue Oval NASCAR engine to not only see the use of electronic fuel injection, but also a distributorless coil-per-plug ignition system. However, the truck series continued to use distributors, so there were provisions in the block for a distributor, to allow the FR9 to be run in either configuration.

The FR9 was the first clean-sheet Blue Oval NASCAR engine design, allowing for a host of high-end features to be incorporated right from the get-go, instead of built-in after the fact. The FR9 was also the first Ford NASCAR engine to use electronic fuel injection and not have a distributor.

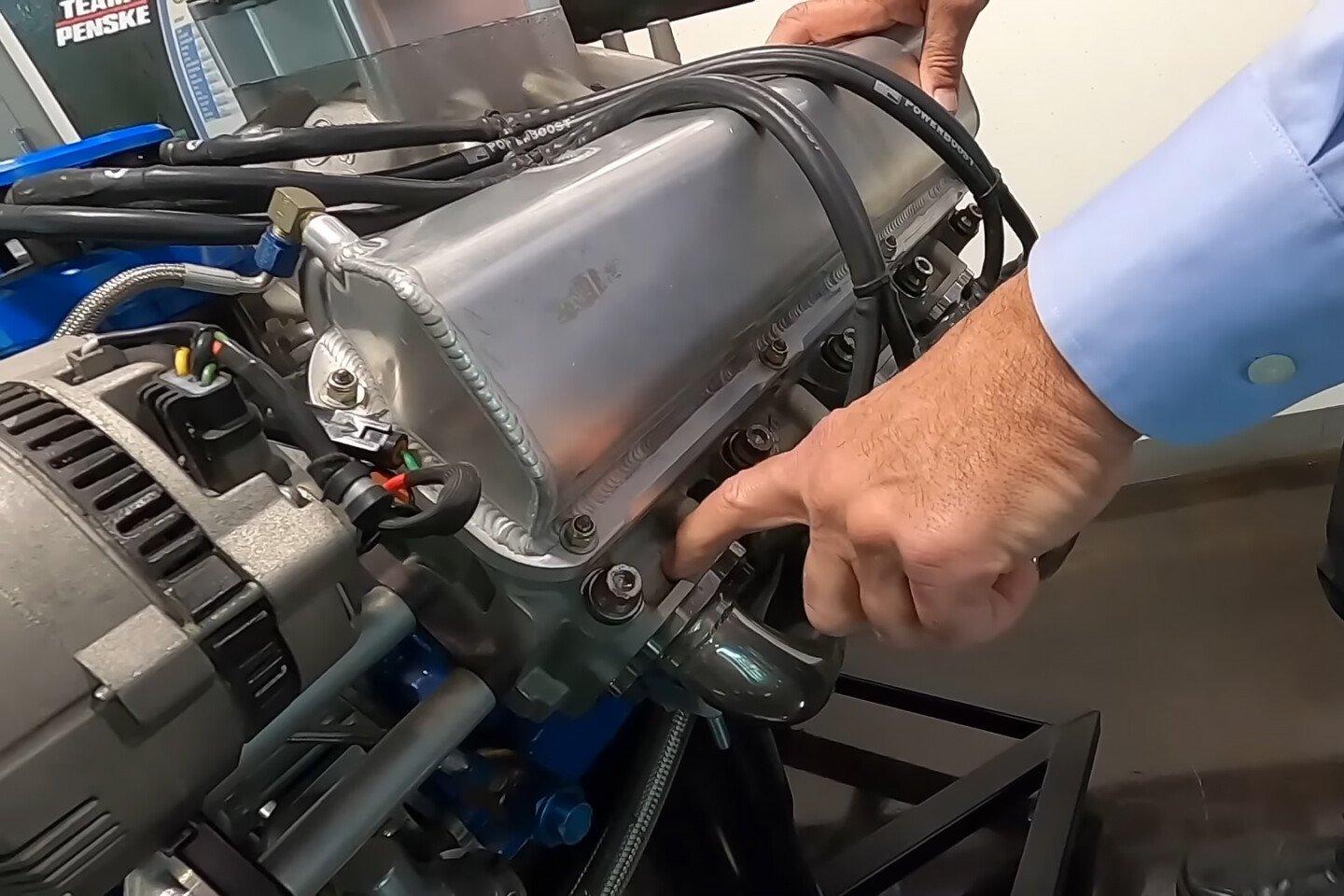

Weight reduction is the name of the game with the FR9, with as much excess material as possible removed from every component in the engine, from the block and cylinder heads, to the intake manifold and water pipes — even the billet valve covers were lightened down to the bare minimum structure, shaving an extra 34 pounds from the engine. Another interesting feature of the FR9 platform was the relocation of the starter motor. In the traditional small-block Ford location, it would get heat-soaked and become problematic. By changing the location and exposing it to open air, failures were eliminated.

“One of the big improvements from C3 to D3 was a reduction in valve spring failures,” says Clark. “That reduction was even more so going from D3 to the FR9. It always seemed to be the number five intake valve spring on the C3 and D3. We felt it was a combination of less oil than the rest of the cylinders and the firing order.”

One of the key design challenges of the FR9 was to eliminate all unnecessary weight from the engine. That led to a lot of components being scalloped and profiled to within an inch of their life, like the water passages below the intake manifold, and the flange of the intake itself.

In only 30 years, the lineup of purpose-built NASCAR engines went from carbureted flat-tappet engines with a distributor making 750 horsepower, to EFI, distributorless, roller-cam engines making well north of 900 horsepower. You had short-blocks that were utterly done after 500 miles, whereas now, single builds are going over 1000 race-miles without being refreshed. “With the new coatings we’re using, we can get a 10,000-mile lifespan out of the FR9 block,” Clark says. Amazing how far we’ve come from junkyard blocks and production parts.