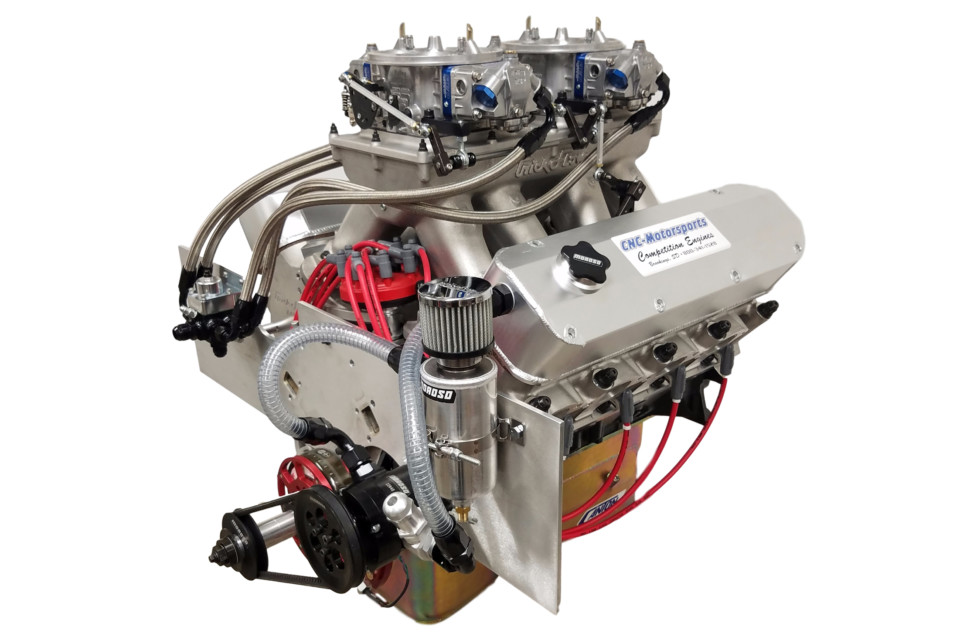

The big-block Ford might fall into the underappreciated category when it comes to Blue Oval powerplants, but there are still applications where they are appreciated and sought-after for their robustness and power-making abilities. While forced-induction may have proven to be the replacement for displacement in some people’s minds, the big-block Ford and its brawny big-cube variants will always have a place in motorsports. Case in point: this 632 cubic-inch big-block Ford designed as a tractor-pulling engine, by CNC-Motorsports.

A tractor-pull engine, outside of the chassis it powers, is almost no different than one designed for drag racing, as both forms of motorsport involve short, wide-open-throttle jaunts at extremely high loads. “When building a pulling engine, it’s very similar to drag racing,” says CNC-Motorsports’ CEO Clint Anderson, noting one difference. “For pulling, we try to build a little wider powerband than we would in drag racing.”

When constructing a big-cube beast which will be spending most of its life at maximum load, you need a solid foundation, and for that, the team went with an Eliminator Performance Products Ultra engine block, which features a host of strength upgrades in order to handle upwards of 2000 horsepower. CNC-Motorsports punched the bores out to a final diameter of 4.600 inches, which is below the max bore size for the block, leaving plenty of meat on the cylinder walls.

The Moroso vacuum pump helps the .043-inch Total Seal AP rings maintain their seal throughout this engine’s sizable powerband.

It’s only fitting that such a serious engine be outfitted with a serious crankshaft. For that, CNC turned to Callies for one of their Magnum-series crankshafts with a 4.750-inch stroke. Made from 4340 steel, and featuring a host of performance attributes, like gun-drilled mains and fully profiled counterweights, the Callies Magnum crank thrives in the insane conditions of a 1,100-plus horsepower engine.

Attached to the crankshaft are a set of Callies’ Ultra I-beam rods, which have been designed for severe-duty use. Made from 4330V steel, the rods are forged with a unique geometry which has been designed to specifically combat the stresses a rod sees in this application. Since this engine not only makes loads of power, but also spins higher than you might expect, having connecting rods that are up to the task is critically important.

Attached to those rods are a set of custom slugs from Diamond Racing Pistons. The ring pack on this severe-duty engine is surprisingly thin – at least to us – with the top and second ring measuring in at .043-inch thick with a 3/16 oil control ring. In order to ensure a long service life and minimal blowby, the CNC team chose a set of Total Seal Advanced Profiling stainless steel rings to fill the gaps.

Clevite H-Series bearings are used for both the rod and main journals, while a Kaase oil pump and Canton oil pan work together to make sure the engine has all of the lifeblood it needs during its 8,000-rpm jaunts. A Cloyes roller timing set and aluminum cover keeps everything in time. A Moroso vacuum pump system helps the engine maintain vacuum, which is constantly in short supply in an engine like this.

A camshaft, ground to CNC-Motorsports exact specifications controls the valves. While they weren’t willing to disclose all of the specs, it was revealed that there was .819 inch of lift on the intake side and .812 inch on the exhaust. Crower solid roller lifters ride on the cam lobes, and move the Trend Performance 7/16-inch, .165-inch wall-thickness pushrods against the Crower shaft rocker system.

The cylinder heads are Trick Flow Specialties A460 castings, which have been completely ported by CNC-Motorsports. Massive 2.400-inch intake and 1.888-inch exhaust valves from Ferrea were installed into the head with PAC valvesprings designed to handle such heavy use. The intake ports flow a whopping 453 cubic feet per minute at .800-inch of valve lift, and 321 cfm on the exhaust side, at the same lift.

An MSD crank trigger, Pro-Billet distributor and wires have the daunting task of keeping the candles lit on this beast under some severely harsh conditions.

A Trick Flow tunnel ram intake sits atop the A460 heads, and is topped off with a pair of AED 1250 cfm Max Pro Dominator carburetors, which have been built for the alcohol the engine consumes as fuel and tuned specifically for tractor-pulling competition. An MSD crank trigger system combined with and MSD distributor and spark plug wires are utilized to keep the spark lit on the combination, while Fel-Pro gaskets seal up the engine, and Cometic head gaskets hold in the sizable combustion pressures.

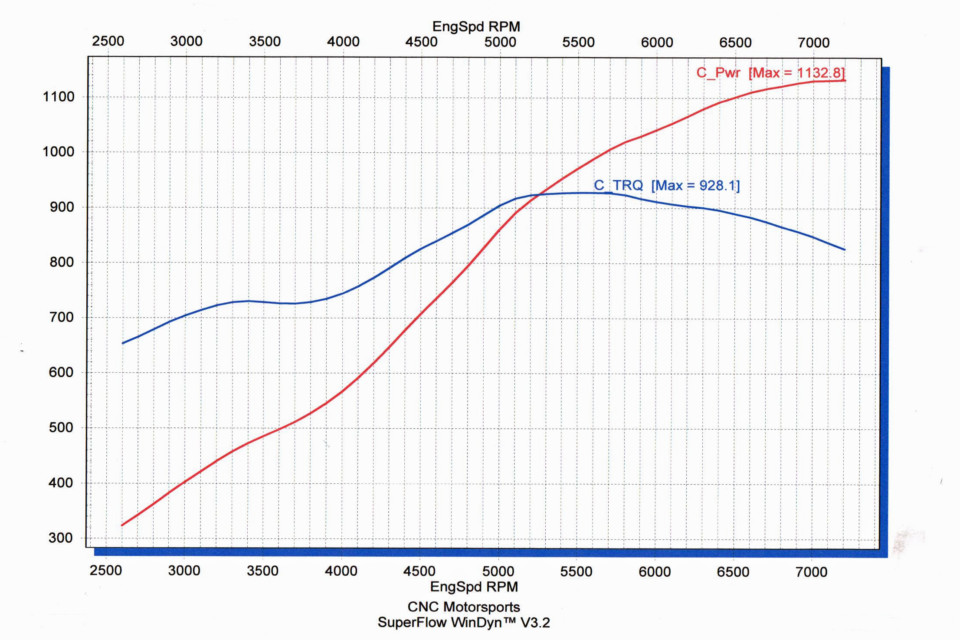

“This engine was built for an open, naturally aspirated class, rules-wise,” says Anderson. “We spun the engine to 7,200 rpm on the dyno, but this engine will be spun 8,000 rpm when in action.”

On the dyno, the engine produced a whopping 1,132 horsepower at 7,200 rpm, with peak torque of 928 lb-ft at 5,600 rpm. Those are pretty high engine speeds when you are talking about big blocks, but for a max-effort competition engine, it’s not out of the realm of normalcy.

In case you were wondering, this engine isn’t just strong, but was built to have some longevity. “It depends on the customer’s maintenance program, but I estimate about 40-50 hooks before it needs to be freshened,” Anderson says. “Most customers have us refresh their engine every other year.” Two seasons on an engine of this caliber is impressive, no doubt.

It’s not every day you see a 1,100-plus horsepower naturally aspirated big-block Ford designed for pulling, but then again, we don’t run across many tractor pulling engines, period. So getting an inside look at this awesome naturally aspirated big-block Ford is a special treat.

This powerband is absolutely incredible, especially considering this is a naturally aspirated, undersquare, big-block engine. Anderson commented that a pulling engine is designed in a similar manner to a drag racing engine, but with a wider powerband. It looks like that was achieved here, especially considering that even though the dyno stops at 7,200 rpm, it will spin into the 8,000-rpm range in competition.